- 11 -

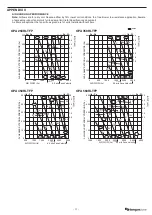

APPENDIX II

AIR HANDLING PERFORMANCE

Note: Airflows are for a dry coil. Reduce airflow by 10% in wet coil conditions. In a free blow or low resistance application, beware

of exceeding indoor fan motor’s full load amp limit (refer Specifications document).

As filters are optional, the fan air flows given are for units installed without filters.

OPA 560RLTFP

OPA 250RLTFP

l/s - Pa

OPA 350RLTFP

l/s - Pa

l/s - Pa

OPA 450RLTFP

500

1000

1500

2000

2500

0

100

200

300

AIR FLOW (l/s)

AV

AILABLE EXTERNA

L PRESSURE (

Pa)

2.5 m/s Face Velocity

400

500

0

NOMINAL

9V

8V

7V

5V

6V

9V

8V

7V

6V

5V

3.1

2.2

1.5

4.9

2.5

1.7

3.4

1.1

INPUT

(kW)

2.5

1.5

0.5

2.0

1.0

3.0

3.5

Amps

500

1000

1500

2000

2500

0

100

200

300

AIR FLOW (l/s)

AV

AILABLE EXTERNA

L PRESSURE (

Pa)

2.5 m/s Face Velocity

400

500

0

NOMINAL

INPUT

(kW)

3.0

2.0

1.0

2.5

1.5

3.5

4.0

8V

7V

5V

6V

9V

8V

7V

6V

5V

2.9

2.0

1.5

1.0

4.7

2.4

3.4

4.3

1000

1500

2000

2500

3000

0

100

200

300

AIR FLOW (l/s)

AV

AILABLE EXTERNA

L PRESSURE (

Pa)

2.5 m/s Face Velocity

400

500

500

NOMINAL

9V

8V

7V

5V

6V

10V

8V

7V

6V

9V

10V

5V

4.5

3.9

2.8

2.0

5.4

3.3

1.0

2.3

1.7

4.6

1.4

INPUT

(kW)

3.0

1.0

2.0

0.0

4.0

5.0

l/s - Pa

- - - - l/s - W

- - - - l/s - W

- - - - l/s - W

- - - - l/s - W

2000

2500

3000

3500

4000

0

100

200

300

AIR FLOW (l/s)

AV

AILABLE EXTERNA

L PRESSURE (

Pa)

2.5 m/s Face Velocity

400

500

1500

1000

NOMINAL

9V

8V

7V

5V

6V

10V

10V

9V

8V

7V

6V

5V

6.1

5.1

3.5

2.5

6.7

4.0

1.2

1.9

1.3

5.6

1.8

INPUT

(kW)

3.0

1.0

2.0

0.0

4.0

5.0

2.8