TMP4100-Series Installation/Maintenance

33480D01.DOC

2-5

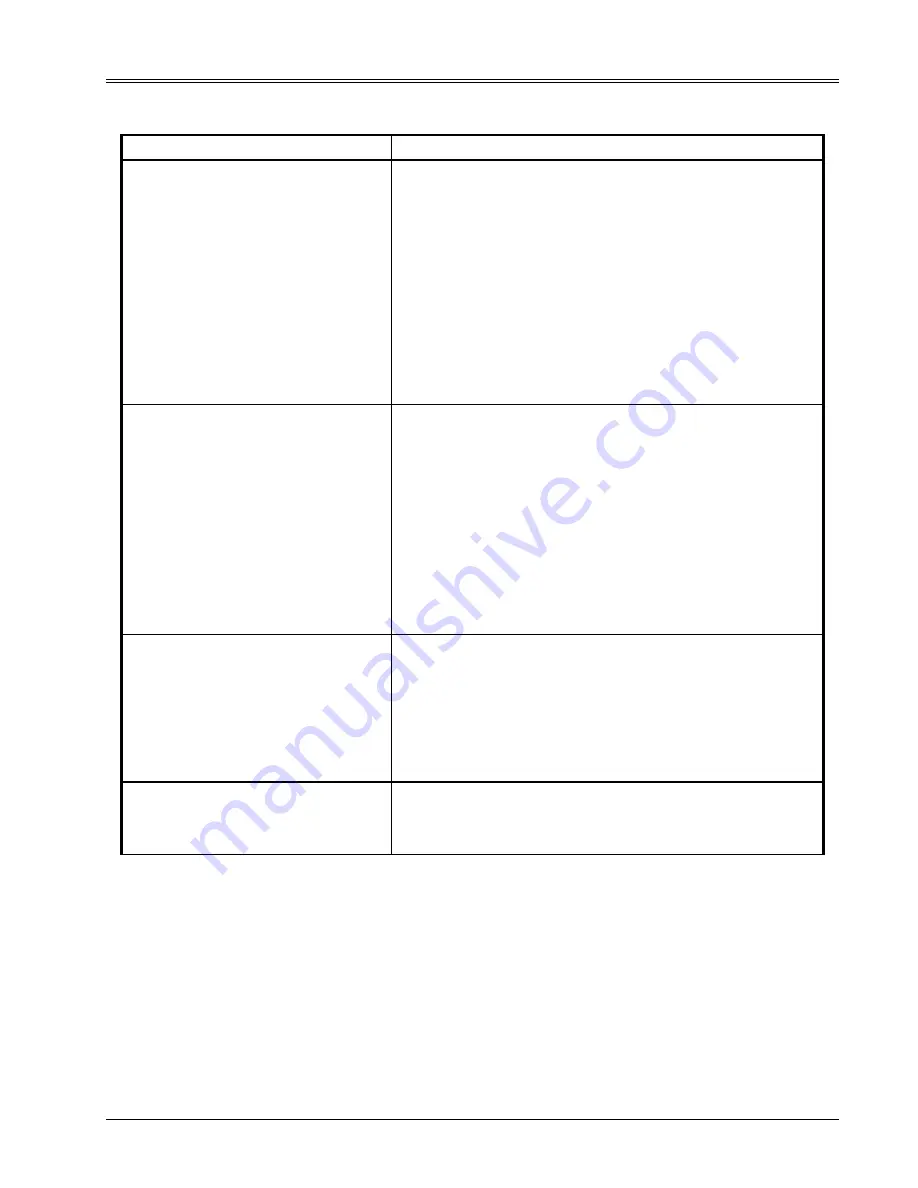

Table 2-1. Troubleshooting the Marking Head (continued)

PROBLEM CORRECTIVE

ACTION

Marking pin fires but does not mark

1. Ensure the pin stroke does not exceed its maximum limit. Reduce the

distance between the retracted pin and the marking surface as required.

2. Ensure the pin is not binding in the pin cartridge. Clean or replace as

necessary.

3. TMP4100, TMP4150, TMP4155: Ensure the drive air is at least 70 psi (4.8

bars).

4. TMP4150, TMP4155: Ensure the return air is not set too high.

5. TMP4100, TMP4150, TMP4155: Ensure the air lines are not crimped or

broken. Replace as required.

6. TMP4100, TMP4150, TMP4155: Ensure the filter is not clogged. Clean as

necessary.

7. Using the marking system software, display the Marker Properties and

ensure the Marking Speed and Pin Type parameters are set properly.

Poor marking performance

1. If the marker was performing properly in previous marks, check the

fixturing of the part. Poor marks may be caused by the marker having

been moved or by part-fixturing problems.

2. TMP4100, TMP4150, TMP4155: Ensure the drive air is at least 70 psi (4.8

bars).

3. TMP4150, TMP4155: Ensure the return air is properly adjusted.

4. Ensure the pin cartridge bore is not worn. Replace if necessary

5. Ensure the pin is not binding in the pin cartridge. Clean or replace as

necessary.

6. Ensure the pin cartridge movement is not restricted in either axis.

7. Using the marking system software, display the Marker Properties and

reduce the Marking Speed parameter setting, as required.

Marker will not respond to external I/O

(Host, Discrete I/O, or TTL Input)

1. Ensure the marking head cable is securely connected to the marking head

and to the controller.

2. Ensure the controller is energized. Refer to the Controller

Installation/Maintenance Manual.

3. Using the marking system software, place the marker Online.

4. Check for a Serial Communications fault, Discrete I/O fault, or TTL Input

fault, as applicable. Refer to the Controller Installation/Maintenance

Manual.

Marker starts marking in an unexpected

location

1. Using the marking system software, view the pattern object definition(s).

2. Adjust the X/Y Anchor parameters and/or Justification parameter settings,

as required.

(Continued on next page)

Summary of Contents for PINSTAMP TMP4100 Series

Page 2: ......

Page 10: ...TMP4100 Series Installation Maintenance viii 33480D01 DOC This page intentionally left blank...

Page 23: ...TMP4100 Series Installation Maintenance 33480D01 DOC 1 13...

Page 24: ...TMP4100 Series Installation Maintenance 1 14 33480D01 DOC This page intentionally left blank...

Page 25: ...TMP4100 Series Installation Maintenance 33480D01 DOC 1 15...

Page 28: ...TMP4100 Series Installation Maintenance 1 18 33480D01 DOC This page intentionally left blank...

Page 52: ...TMP4100 Series Installation Maintenance 2 24 33480D01 DOC This page intentionally left blank...

Page 54: ...Appendix A A 2 33480D01 DOC This page intentionally left blank...