Versa User Manual

www.teledynetekmar.com

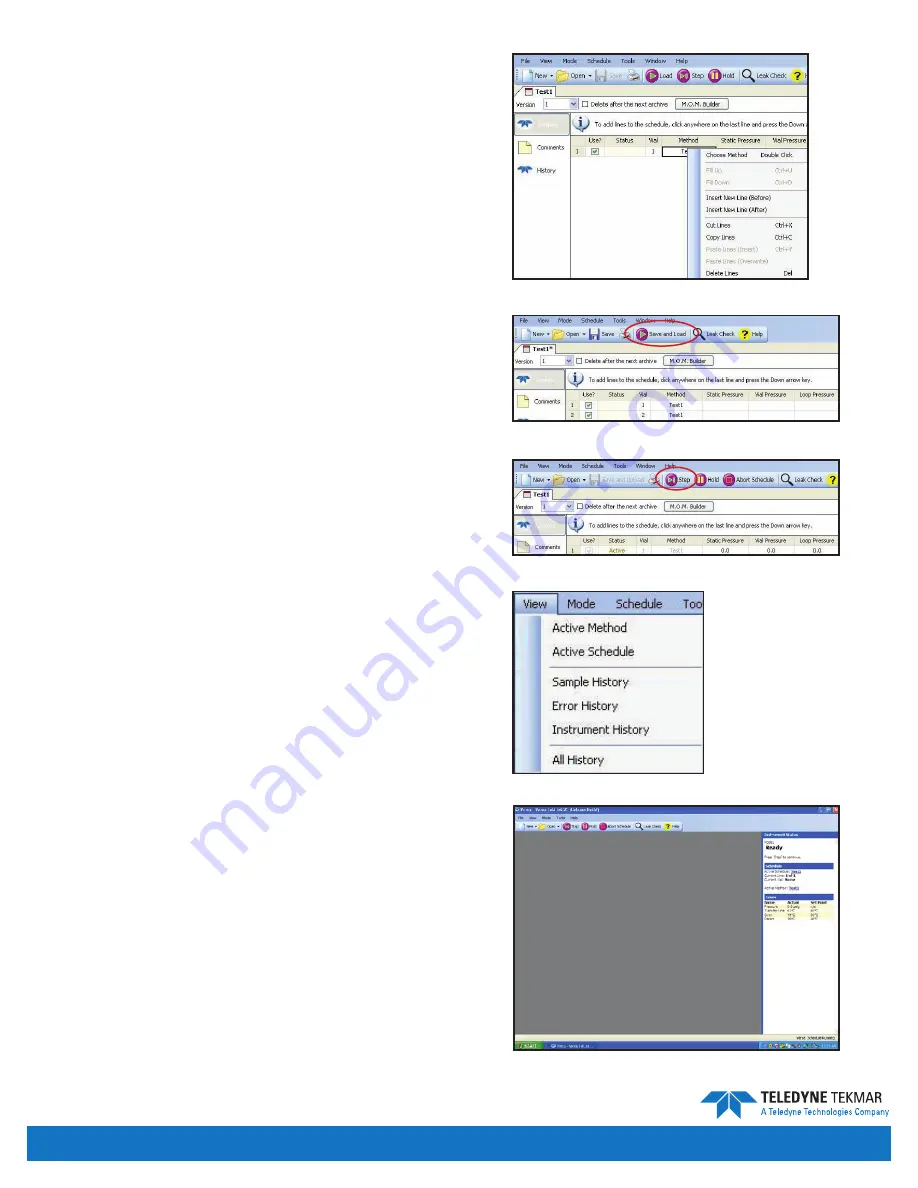

schedule editor

An existing schedule can also be edited by clicking

file |

open | schedule

. Browse to the folder where you store

your schedules and open the desired schedule.

To edit a schedule, click on the line number you wish

to change.

To add, delete, cut, copy, or paste a line of the schedule,

right-click with the mouse and select from the menu.

Select the line where you want the action to occur.

Save and Load

Select

save and load

to save the method and load the

schedule to the Versa.

Start

After the system has reached the set temperatures for all

zones, click the

step

button to start the schedule.

Updating an active schedule

There are a couple ways to open or view an active schedule:

• Click

View | active schedule

.

• Click the active schedule displayed in the

Instrument

status

pane.

note:

You can make schedule changes while the Versa

is running, but you cannot change a line of

the schedule that is currently running, or has

completed. Changes can only be made to the lines

of the schedule that have not yet executed.

Figure 4-18: Right Click Menu

Figure 4-19: Save and Load

Figure 4-20: Step Button

Figure 4-21: View Menu

Figure 4-22: Status Pane

Introduction • Page 4-9

Summary of Contents for 15-0800-074

Page 1: ...Versa User Manual www teledynetekmar com Versa Manual Part 15 0800 074 ...

Page 8: ...Versa User Manual www teledynetekmar com Chapter 1 Introduction ...

Page 21: ...Versa User Manual www teledynetekmar com Chapter 2 Installation Setup ...

Page 36: ...Versa User Manual www teledynetekmar com Chapter 3 Basic Operation ...

Page 44: ...Versa User Manual www teledynetekmar com Chapter 4 Versa TekLink 2G ...

Page 61: ...Versa User Manual www teledynetekmar com Chapter 5 21 CFR Part 11 Compliance ...

Page 77: ...Versa User Manual www teledynetekmar com Chapter 7 Maintenance Troubleshooting ...

Page 90: ...Versa User Manual www teledynetekmar com Chapter 8 Diagrams ...

Page 91: ...Versa User Manual www teledynetekmar com Detailed Plumbing Diagrams Page 8 2 ...

Page 100: ...Versa User Manual www teledynetekmar com Chapter 9 Index ...