Handheld and Benchtop Instruments Basic Service

1

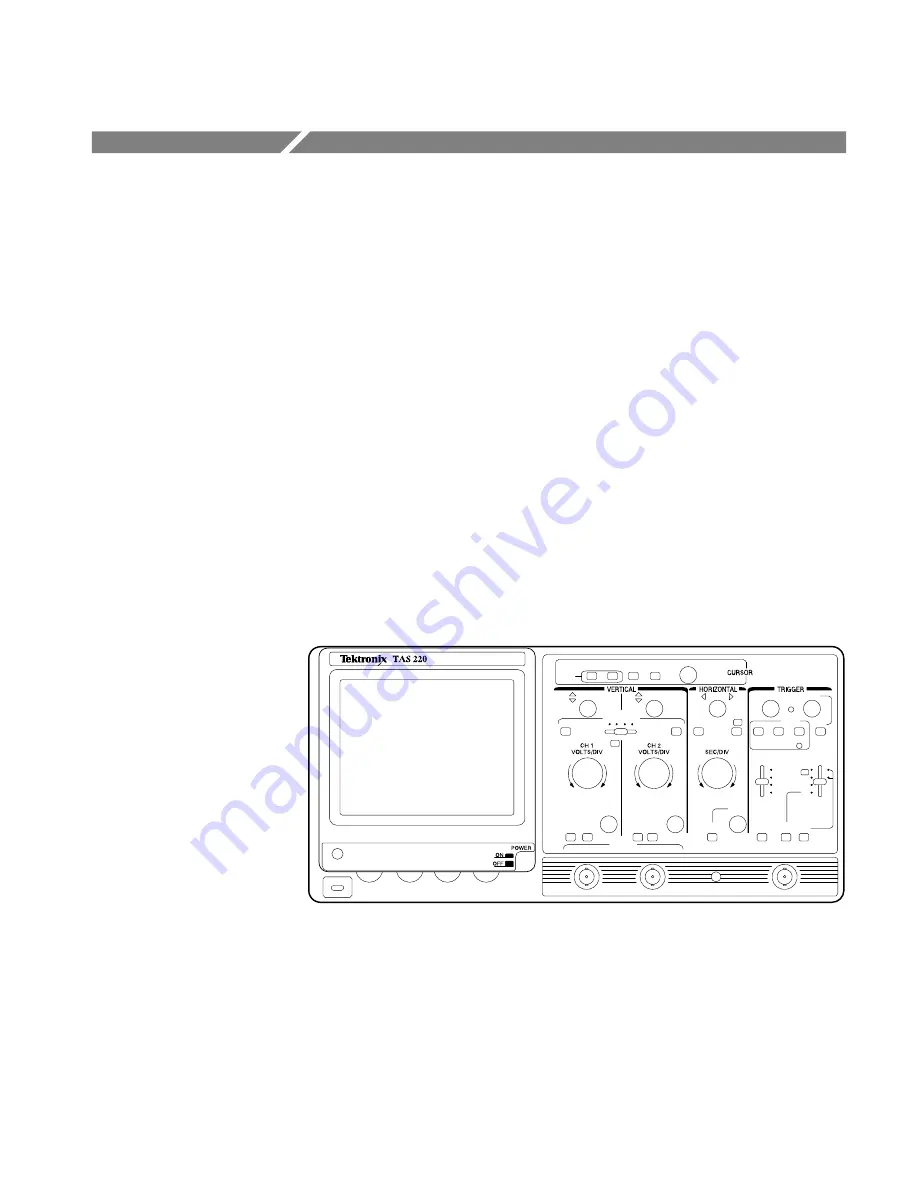

TAS 200 Series Oscilloscopes

The Tektronix TAS 220 and TAS 250 oscilloscopes are dual-channel products

with frequency bandwidths of DC to 20 MHz and DC to 50 MHz respectively.

Both oscilloscopes feature a maximum sensitivity of 1 mV/division and a

maximum sweep speed of 10 ns/division.

In addition, the TAS 200 series oscilloscopes offer the following features:

High beam transmission and high intensity CRT displays for clear

waveforms at high sweep speeds.

High stability low-drift temperature compensation circuits to reduce baseline

and DC balance drift.

Trigger feature, Set to 50% that eliminates triggering adjustments when

displaying regular, video, and large duty-cycle-ratio signals.

Synchronization separator and trigger circuitry that permits the display of

TV signals. (You can automatically select vertical and horizontal signals

with the SEC/DIV control.)

Automatic focus (following an initial intensity adjustment).

Figure 1: TAS 220 Oscilloscope

Summary of Contents for DCM300

Page 10: ...Preventing Electrostatic Discharge viii Handheld and Benchtop Instruments Basic Service ...

Page 13: ...Instructions Manual DCM300 and DCM320 Digital Clamp Multimeters 070 9847 00 ...

Page 15: ...Table of Contents ii Handheld and Benchtop Instruments Basic Service ...

Page 30: ...Instructions Manual DCM330 Digital Clamp Meter 070 9848 00 ...

Page 32: ...Table of Contents ii Handheld and Benchtop Instruments Basic Service ...

Page 49: ...Instructions Manual DCM910 Digital Clamp Meter 070 9849 00 ...

Page 51: ...Table of Contents ii Handheld and Benchtop Instruments Basic Service ...

Page 68: ...Instructions Manual DMM800 Series Digital Multimeters 070 9850 00 ...

Page 70: ...Table of Contents ii Handheld and Benchtop Instruments Basic Service ...

Page 110: ...DMM800 Series Adjustment Procedures 40 Handheld and Benchtop Instruments Basic Service ...

Page 111: ...Instructions Manual DMM912 914 and 916 Digital Multimeters 070 9851 00 ...

Page 113: ...Table of Contents ii Handheld and Benchtop Instruments Basic Service ...

Page 153: ...DMM91X Series Adjustment Procedures 40 Handheld and Benchtop Instruments Basic Service ...

Page 154: ...Instructions Manual DTM500 Series Digital Thermometers 070 9852 00 ...

Page 156: ...Table of Contents ii Handheld and Benchtop Instruments Basic Service ...

Page 173: ...Instructions Manual DTM900 and DTM920 Digital Thermometers 070 9853 00 ...

Page 175: ...Table of Contents ii Handheld and Benchtop Instruments Basic Service ...

Page 192: ...Instructions Manual PS280 and PS283 Power Supplies 070 9894 00 ...

Page 194: ...Table of Contents ii Handheld and Benchtop Instruments Basic Service ...

Page 217: ...Instructions Manual PS2520 Series Power Supplies 070 9854 00 ...

Page 219: ...Table of Contents ii Handheld and Benchtop Instruments Basic Service ...

Page 286: ...Instructions Manual TAS 200 Series Oscilloscopes 070 9855 00 ...

Page 288: ...Table of Contents ii Handheld and Benchtop Instruments Basic Service ...

Page 332: ...TAS 200 Series Adjustment Procedures 44 Handheld and Benchtop Instruments Basic Service ...

Page 333: ...Instructions Manual THM420 Digital Multimeter 070 9856 00 ...

Page 335: ...Table of Contents ii Handheld and Benchtop Instruments Basic Service ...

Page 353: ...THM420 Adjustment Procedures 18 Handheld and Benchtop Instruments Basic Service ...

Page 354: ...Instructions Manual THM500 Series Instruments 070 9857 00 ...

Page 356: ...Table of Contents ii Handheld and Benchtop Instruments Basic Service ...

Page 380: ...THM500 Series Performance Verification 24 Handheld and Benchtop Instruments Basic Service ...

Page 381: ......

Page 382: ......