I.T.S. Ital Trade Services PT 630 Operating Manual

17

17

17

17

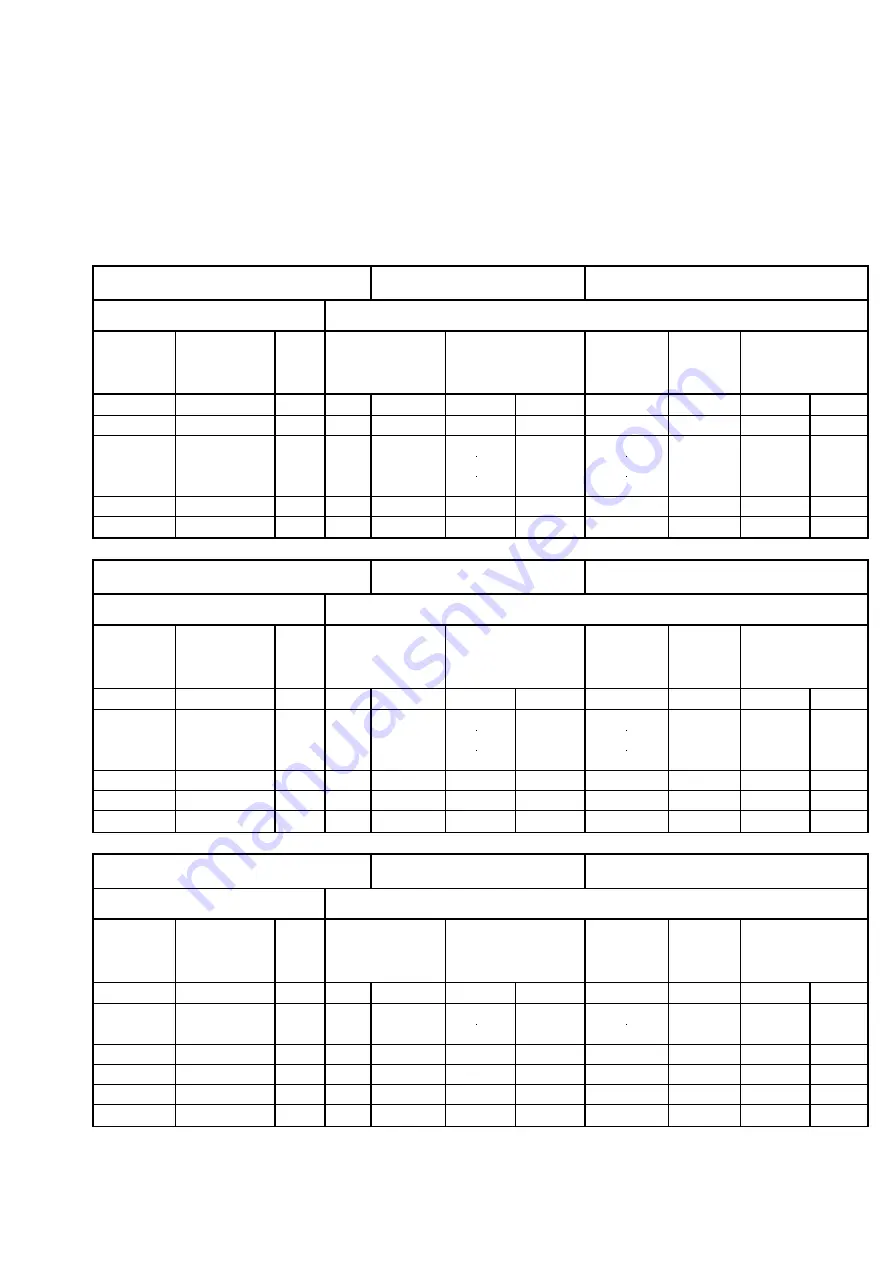

5. Welding Table for PE pipes DVS norm version 2207-1

The following tables show the values to be applied during the welding cycle as per previous instructions and graph.

However in order to clarify once again the meaning of these values please kindly note:

t1

=

Time requested for the bead formation to be done with pressure value =

P1

+ inertial pressure

t2

=

Time requested for the continual heating to be done with pressure value =

P2

+ inertial pressure

t3

=

Time requested for the change over

t4

=

Time requested for bringing up the pressure at the value of pressure =

P1

+ inertial pressure

t5

=

time requested for cooling down to be done with pressure value =

P1

+ inertial pressure

Important

Remember always to add the value checked of inertial pressure to the P1 and P2 values !!!!!!!

PT 630 - DVS 2207-1

Cyl. section cm

2

17,3

Welding range 315-630 mm

material PE80-100

SDR 41

D

S

T

P1

bead

P2

t 2

t 3

t 4

P5

t 5

DIAMETER

WALL THICK.

TEMP.

BEAD FORMATION

HEATING UP

CHANGEOV.

RAMP

COOLING

mm

mm

°C

bar

mm

bar

sec

sec

sec

bar

min

315

7,7

215

6,4

1,5

0.. 0,4

77

0..

6

6

6,4

11

355

8,7

214

8,2

1,5

0.. 0,5

87

0..

7

7

8,2

12

400

9,8

213

10,4

1,5

0.. 0,7

98

0..

7

7

10,4

13

450

11,0

212

13,1

1,5

0.. 0,9

110

0..

8

8

13,1

15

500

12,2

211

16,2

2,0

0.. 1,1

122

0..

8

8

16,2

16

560

13,7

210

20,3

2,0

0.. 1,4

137

0..

8

9

20,3

18

630

15,4

209

25,7

2,0

0.. 1,7

154

0..

9

9

25,7

20

PT 630 - DVS 2207-1

Cyl. section cm

2

17,3

Welding range 315-630 mm

material PE80-100

SDR 33

D

S

T

P1

bead

P2

t 2

t 3

t 4

P5

t 5

DIAMETER

WALL THICK.

TEMP.

BEAD FORMATION

HEATING UP

CHANGEOV.

RAMP

COOLING

mm

mm

°C

bar

mm

bar

sec

sec

sec

bar

min

315

9,5

213

7,9

1,5

0.. 0,5

95

0..

7

7

7,9

13

355

10,8

212

10,1

1,5

0.. 0,7

108

0..

8

8

10,1

15

400

12,1

211

12,8

2,0

0.. 0,9

121

0..

8

8

12,8

16

450

13,6

210

16,2

2,0

0.. 1,1

136

0..

8

9

16,2

18

500

15,2

209

20,

2,0

0.. 1,3

152

0..

9

9

20,

20

560

17,0

207

25,1

2,0

0.. 1,7

170

0..

9

10

25,1

22

630

19,1

206

31,8

2,5

0.. 2,1

191

0..

10

11

31,8

24

PT 630 - DVS 2207-1

Cyl. section cm

2

17,3

Welding range 315-630 mm

material PE80-100

SDR 27,6

D

S

T

P1

bead

P2

t 2

t 3

t 4

P5

t 5

DIAMETER

WALL THICK.

TEMP.

BEAD FORMATION

HEATING UP

CHANGEOV.

RAMP

COOLING

mm

mm

°C

bar

mm

bar

sec

sec

sec

bar

min

315

11,4

212

9,4

1,5

0.. 0,6

114

0..

8

8

9,4

15

355

12,9

210

12,

2,0

0.. 0,8

129

0..

8

8

12,

17

400

14,5

209

15,2

2,0

0.. 1,0

145

0..

9

9

15,2

19

450

16,3

208

19,3

2,0

0.. 1,3

163

0..

9

10

19,3

21

500

18,1

207

23,8

2,0

0.. 1,6

181

0..

10

11

23,8

23

560

20,3

205

29,8

2,5

0.. 2,0

203

0..

10

12

29,8

25

630

22,8

204

37,7

2,5

0.. 2,5

228

0..

11

13

37,7

28

Warning!: in case of PE100 welding, temperature T must be increased to 220°c

Summary of Contents for I.T.S. PT 630

Page 1: ...I T S by Tecnodue PT 630 Edition 1208 Operating Manual ...

Page 26: ...I T S Ital Trade Services PT 630 Operating Manual 26 26 26 26 9 4 Hydraulic plan ...

Page 29: ...I T S Ital Trade Services PT 630 Operating Manual 29 29 29 29 ...

Page 31: ...I T S Ital Trade Services PT 630 Operating Manual 31 31 31 31 ...

Page 33: ...I T S Ital Trade Services PT 630 Operating Manual 33 33 33 33 ...