■

Contrast

– display contrast.

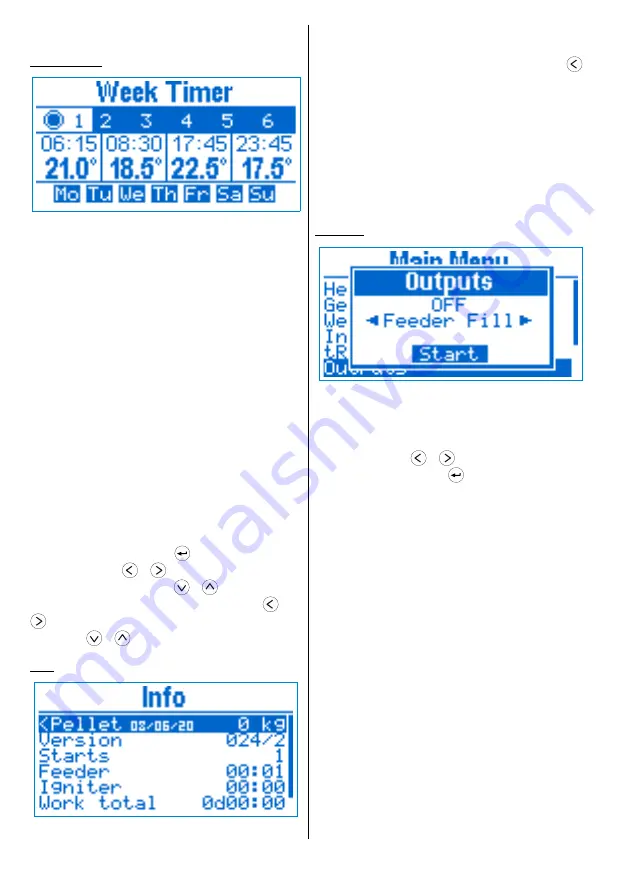

Week Timer

Fig 10

Week timer

Using the week timer, the user can specify a

temperature for a particular time interval of the day

for a given day of the week. It consists of 6 programs,

each one having 4 timers that specifies time and

temperature. The time of every next timer must be

after the previous one, as a value of

--:--

means

that the timer is not active. For example the timer

configuration on

Fig 11

temperatures and periods:

■

07:45 - 08:44

21.0°C

■

08:45 - 17:44

18.5°C

■

17:45 - 23:44

22.5°C

■

23:45 - 07:44

17.5°C

Every program can be active and applied to

specific days of the week. In case more than one

program is active for a given day of the week, the

higher priority program is the one with bigger

number.

Use the navigation buttons to select the current

element you want to edit (program, time,

temperature and day of week). Parameter editing is

initiated by pressing button

. While editing time,

using the buttons

/

you decrease / increase

the time by

15 min

, as with

/

by

1 hour

.

While editing temperature, using the buttons

/

you decrease / increase the temperature by

0.5

°C, as with

/

by

2

°C.

Info

Fig 11

Information

On this screen usage information is displayed:

■

Pellet

– counter for the pellets burned from

the last reset. In order to reset it, hold the button

until you hear a sound signal. The counter is reset

and the date is set to the current one.

■

Version

– firmware version

■

Starts

– controller power on count

■

Feeder

– total feeder work time (HH:MM)

■

Lighter

– total lighter work time (HH:MM)

■

Work total

– device total work time

(DddHH:MM)

■

First Start

– date of first start

Outputs

Fig 12

Outputs

You can manually control the outputs

Feeder

and

Fan

. This is only possible if the device is in

OFF

mode.

Use the buttons

/

to choose the output you

want to control and press

to start / stop it. When

an output is activated, a 4 min timer will stop it

automatically when it expires.

■

Feeder Fill

The Feeder Fill function is used when the device is

first powered on, or if the pellets have run out during

normal operation.

In case the feeder is empty, turn it on until some

pellets start coming down in the work area. If the

feeder is not full, then during the ignition phase less

pellets will be fed, which may lead to ignition failure.

■

Fan

Fan function can be used for cleaning the burning

chamber from ashes.

6

Using the device