5. Channel setup

Operation Manual Version 1.6

46

Coupling

Description

Ground

Input+ and Input- will be shorten to channel ground.

The output signal is 0V.

Differential Ended DC

The differential signal between Input + und Input – will

be amplified and outputted.

Differential Ended 3Hz High Pass Filter

As „Differential Ended DC“, but the signal will be

filtered by a 3Hz high pass. No DC components of the

measurement signal will be outputted.

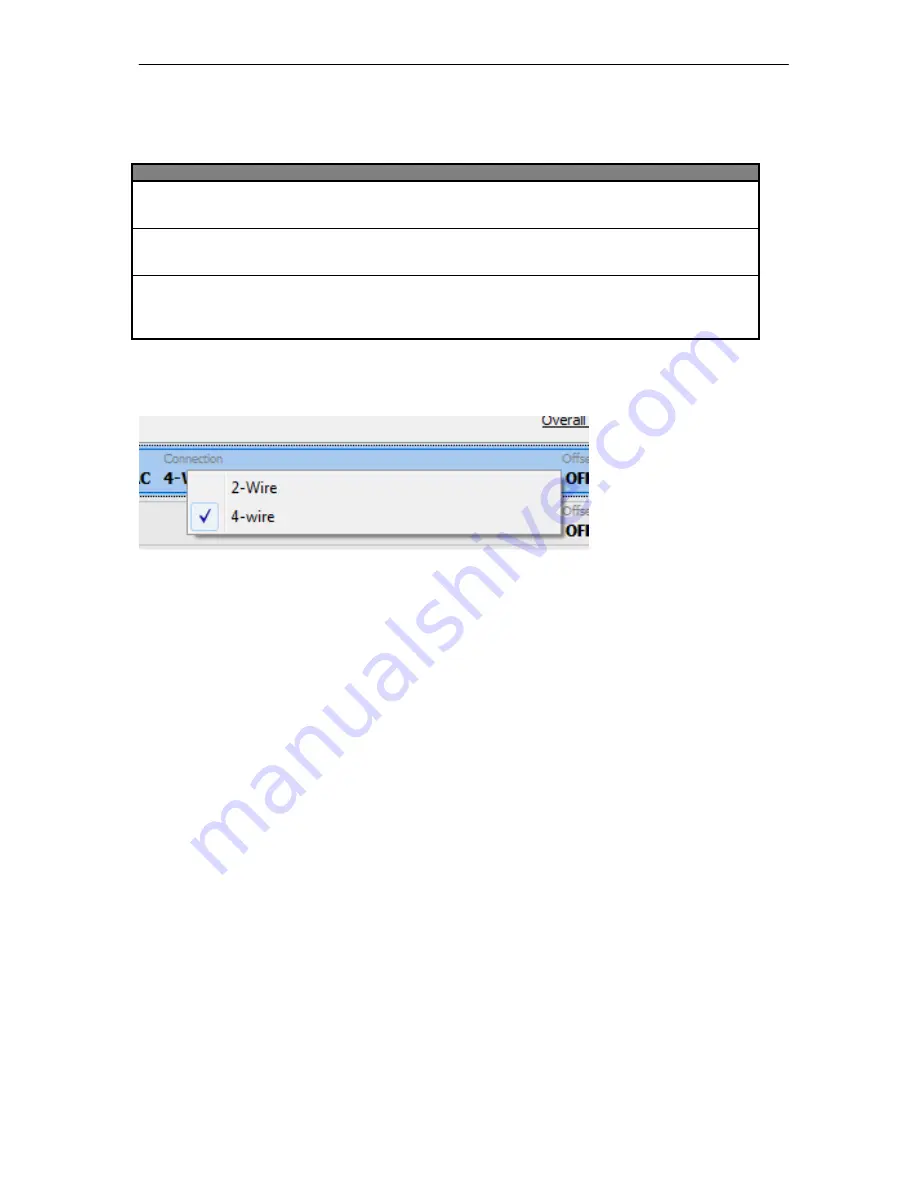

In the column Connection you can select 2-wire or 4-wire measurement. In the case of 4-wire, the power supply

of the sensor takes other wire as the measurement wire. The measurement signal is then not influenced by the

power supply.