SETTING INJECTION PUMP TIMING

Adjustment of injection pump requires expertise

and special equipment; the inspection must be

performed only at authorized service centers.

Operator instructions provided in this section are

only for information purpose.

A certain amount of variation can apply to the

injection pump timing due to mechanical wear.

This problem is indicated by the loss of engine

power, the exhaust gas becoming extremely black

and the engine making greater noise.

In some cases white exhaust gas can be observed

in high altitude geographical regions; ignition

advance may need to be adjusted for proper

engine performance.

Factory setting for engine ignition advance is 12°.

For adjustment, perform the following in the same

order:

1.

Remove the engine shut-off solenoid or place

the key to ignition-1.

2.

Remove the safety frame and check the lines

on the flywheel looking through the peep hole

on the right side of the flywheel housing or

track top dead centers or ignition timings by

checking the lines on the crank pulley.

3.

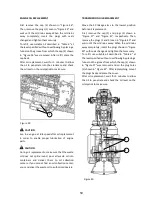

To find the "1,4 AZ' sign on the flywheel, twist

the flywheel (see “Figure 67”). You can twist

the flywheel by placing a ring spanner to the

hub (see “Figure 66”)

Definitions for the abbreviations on the flywheel

are as follows:

“1,4 AZ”: Injection timing for 1

st

or 4

th

cylinder.

“1,4 UN”: Top dead center timing for 1

st

or 4

th

cylinder.

“2,3 AZ”: Injection timing for 2

nd

or 3

rd

cylinder.

“2,3 UN”: Top dead center timing for 2

nd

or 3

rd

cylinder.

There is a 360° (one crankshaft cycle) phase

difference between the first cylinder and fourth

cylinder.

There is a 360° (one crankshaft cycle) phase

difference between the second cylinder and third

cylinder.

4.

When the sign is found, turn the crankshaft

about 30° counterclockwise (when viewed

from the front of the engine).

5.

"1,4 AZ', means injection timing for cylinders 1

or 4.

6.

To turn the crankshaft by holding with a ring

spanner, use a special service tool (ring

spanner). Remove the high pressure pipe.

7.

Slightly loosen the nozzle holder, the part (1)

shown in “Figure 68” and tighten after filled

with fuel as seen in “Figure 68”.

8.

Wipe the fuel on the nozzle holder with a clean

cloth and leave only a small amount of fuel.

9.

Observe the fuel on the nozzle holder by slowly

turning the crankshaft clockwise (when viewed

from the front side of the engine).

10.

The moment when the fuel on the nozzle

holder increases abruptly is injection timing.

11.

If the fuel increases too much, it means the

injection time have passed. To identify the

time when the fuel amount increases, repeat

the procedure above.

62

Figure 67

CAUTION

Figure 66

Summary of Contents for 850

Page 1: ......

Page 2: ......

Page 7: ......

Page 12: ......

Page 24: ...12 ...

Page 28: ...16 ...

Page 50: ...38 ...

Page 54: ...42 ...

Page 78: ...PROPER BATTERY SERVICE AND TIPS FOR SAFETY Table 7 66 ...

Page 86: ...74 ...

Page 87: ...SECTION 7 TECHNICAL SPECIFICATIONS Figure 83 Table 8 Technical Specs 75 ...

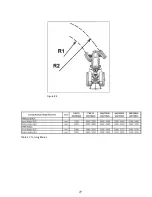

Page 89: ...Figure 84 Table 11 Turning Radius 77 ...

Page 94: ...82 ...

Page 100: ...88 ...

Page 101: ......