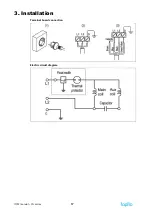

3. Installation

IOM manual

–

SG series

12

3.

Installation

3.1.

Precautions

DANGER:

Disconnect and lock out electrical power before installing or servicing the unit.

WARNING:

➢

Do not install the pump in an explosion hazard zones.

➢

Make sure that the unit cannot roll or fall over and injure people, or damage property.

WARNING:

Electrical shock hazard. Check that, the cable and cable gland have not been damaged during

transport before installing the pump.

NOTICE

: Never force piping to make a connection with a pump.

These requirements apply:

➢

Use the pump dimensional drawing in order to ensure proper installation.

➢

Provide a suitable barrier around the work area, for example, a guard rail.

➢

Remove all debris from the pump inlet before you install the pump.

➢

Always check the impeller rotation before submerging the pump into liquid.

CAUTION:

➢

The supply voltage variation:

➢

continuous running: max±5% of the rated voltage.

➢

intermittent running: max±10% of the rated voltage.

➢

Pump should operate in water temperature between 0

o

C and 40

o

C.

➢

The pump should be used only for pumping plain water. The pump should not be used

to pump fluids such as oil, saltwater, or organic solvents.

➢

The pump must not be used in a partially disassembled state.

➢

Do not use the pump in an area where the water pressure exceeds the given values

(see chapter 3.2.

Maximum allowable operating pressure and maximum immersion

depth

) , as it may damage the pump, or cause a short or electrical shock.

3.2.

Maximum allowable operating pressure and maximum

immersion depth

Pump models

Maximum allowable operating pressure

All models

2 bar (29 PSI) total, immersion combined with discharge pressure

Maximum allowable operating pressure defines maximum immersion depth. For more

information contact Tapflo.