17

Moment

Done

Note

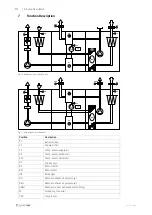

Select the menu

Configuration > Functions >

Temperature control

:

•

Set

Cooling recovery mode

to

On

Select the menu

Configuration > I/O allocation

settings > Digital outputs

:

•

Set Signal for

Step controller 1 step 1

to

DO4

•

Set Signal for

Step controller 1 step 2

to

DO5

Select the menu

Configuration > I/O allocation

settings > Digital inputs

:

•

Set Signal for

Extended operation normal speed

to Select I/O (or to any other free DI)

•

Set Signal for

Feedback cooling (SEQ-C)

to

DI4

Note:

Note: DI4 cannot be used for extended run

when Topvex SoftCooler is used.

Select the menu

Data & Settings > Temperature

control > Cooling

:

•

Set

Min switch time

to 60 s

•

Set

Step 1 start point

to 10%

•

Set

Step 1 stop point

to 0%

•

Set

Step 2 start point

to 10%

•

Set

Step 2 stop point

to 5%

•

Set

Reduction of min limit supply air if

active DX-cooling

to 0 °C

8.4

Before first compressor start

To avoid damage on the compressor the oil in the compressor crankcase must be heated before the first start.

Moment

Done

Note

Stop the Supply- and extract fan (via the Topvex air

handling units safety switch)

Turn on the mains supply for the Topvex SoftCooler via the

working switch, make sure that the voltage is on (the

display in the frequency converter lights up)

Wait for

minimum 2 hours so that the oil will reach about +30° C!

8.5

Control cooling operation

Moment

Done

Note

Start the Supply- and extract fan (via the Topvex air

handling units safety switch). Run the unit on dimensioning

airflows.

Supply air ________________m

3

/h

Extract air _______________m

3

/h

Start the compressor by establishing a 100% cooling

demand:

• Log in with service level using password 0612

• Select menu

Data & Settings > In-/Output

status > Heating/Cooling sequences

• Set Mode for

Cooling

to

Manual

• Set Manual for

Cooling

to 100%

Run the compressor for at least 10 minutes.

Then read the Extract-, Outdoor- and Supply air

temperature via the display of the control unit (in the menu

Temperature

).

Outdoor air temperature __________°C

Supply air temperature ___________°C

Extract air temperature __________°C

Let the compressor run.

Measure the hotgas- and liquid line temperature with a

strap-on temperature detector.

Hotgas temperature ___________°C

Liquid line temperature _________°C

208767 | A006

Summary of Contents for Topvex TR 09 Series

Page 2: ...208767 A006...

Page 4: ......

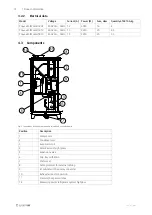

Page 14: ...10 Installation A Fig 6 Illustration shows the left handed version of the unit 208767 A006...

Page 23: ...208767 A006...