16

8

Commissioning protocol

Company:

Responsible:

8.1

General

Customer:

Date:

Installation:

Object/unit:

Item no:

Installation address:

Model/size

Serial no:

Designation:

8.2

Installation control

Moment

Done

Note

Control report cooling concerning installation established.

(Application shall in some cases be done, see chapter 3,

Refrigerant Control/Reporting).

All unit parts undamaged.

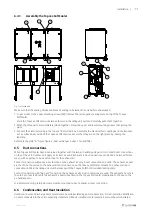

Installation carried out according to instructions (see

chapter 6.4.1, Assembly the Topvex SoftCooler and

chapter 6.5, Duct connections).

Condensation drain connected (see chapter 6.7,

Condensation drain).

Mains supply connected via the Safety switch (see chapter

6.8, Electrical connection).

By-pass damper connected when such is to be used,

accessory (see chapter 6.8.1, External/Internal

connections).

Internal operating cable connected (see chapter 6.8.1,

External/Internal connections).

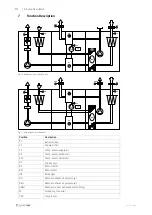

The two transparent pressure measuring tubes to the

extract fan connected thru the Topvex SoftCooler

Supply and extract airflow adjusted

8.3

Preparing the control unit

To receive correct functions the following settings must be done in the control unit. Log in with service level using pass-

word 0612.

Moment

Done

Note

Select the menu

Configuration > Functions >

Function activation > Heating/Cooling

sequence setup

:

• Choose

Cooling

• Set

Type of cooler

to

DX

• Set

Type of feedback

to

Alarm

Select the menu

Configuration > Functions >

Function activation > Heating/Cooling

sequence setup

:

•

Choose

Step controller 1

•

Set

Step control sequence

to

Cooling

•

Set

Number of steps

to 2

Select the menu

Configuration > Functions >

Function activation

:

•

Check that

Temperature control type

is set as

Extract air cascade

or

Room cascade

208767 | A006

Summary of Contents for Topvex TR 09 Series

Page 2: ...208767 A006...

Page 4: ......

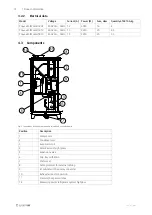

Page 14: ...10 Installation A Fig 6 Illustration shows the left handed version of the unit 208767 A006...

Page 23: ...208767 A006...