10

D200-41-00

Pittway Tecnologica S.r.l, Via Caboto 19/3, 34147 Trieste, Italy

TESTING

Testing should only be carried out by qualified

personnel. Before undertaking any testing ensure that

the proper authorities have been informed, and if

necessary, that the unit has been isolated from the fire

control panel to prevent unwanted alarms.

Sensor Testing

With the unit powered up and the top cover removed

the sensors can be tested for functionality using methods

described by the manufacturer (for example aerosol spray

or magnet test).

System Testing

Alarm: The installed system must be checked with the top

cover securely fitted. As a minimum, smoke should be

introduced to the furthest sampling point from the A300E

unit on each branch of the pipe. The choice of smoke

source is dependant on the installation but in all cases the

smoke must be present for the duration of the test –

aerosol sprays for point detectors DO NOT work on

aspirated systems.

If it is possible to get close to the sampling point then a

basic, functional check can be carried out with smoke

matches or lighted taper etc. But for measurable

performance tests then refer to Appendix A of the FIA Code

of Practice for Aspirating Systems to select the

appropriate test for the installation.

Fault: Simulate a fault on the A300E unit (for example,

remove the power) and check that a fault is signalled at the

fire panel.

MAINTAINANCE

With normal use, the filter elements will eventually become

contaminated with dust particles, impeding airflow. It is

recommended that it be changed every six months.

To change the filter:

1. Unscrew the top cover

2. Lift out the foam filter elements from its housing

3. Fit a new filter kit so that it lies flush with the top of its

housing

4. Replace the top cover

5. Test the unit as described above.

IMPORTANT

To ensure maximum efficiency and longevity of the filter,

when fitting the replacement filter element kit, the Coarse

filter needs to be fitted first into the pipe.

ACCESSORIES

The following accessories are available to order:

Model Number

Product

02-FL50

Replacement Filter Element Kit

20-LA0015

Replacement Key to Open Detector

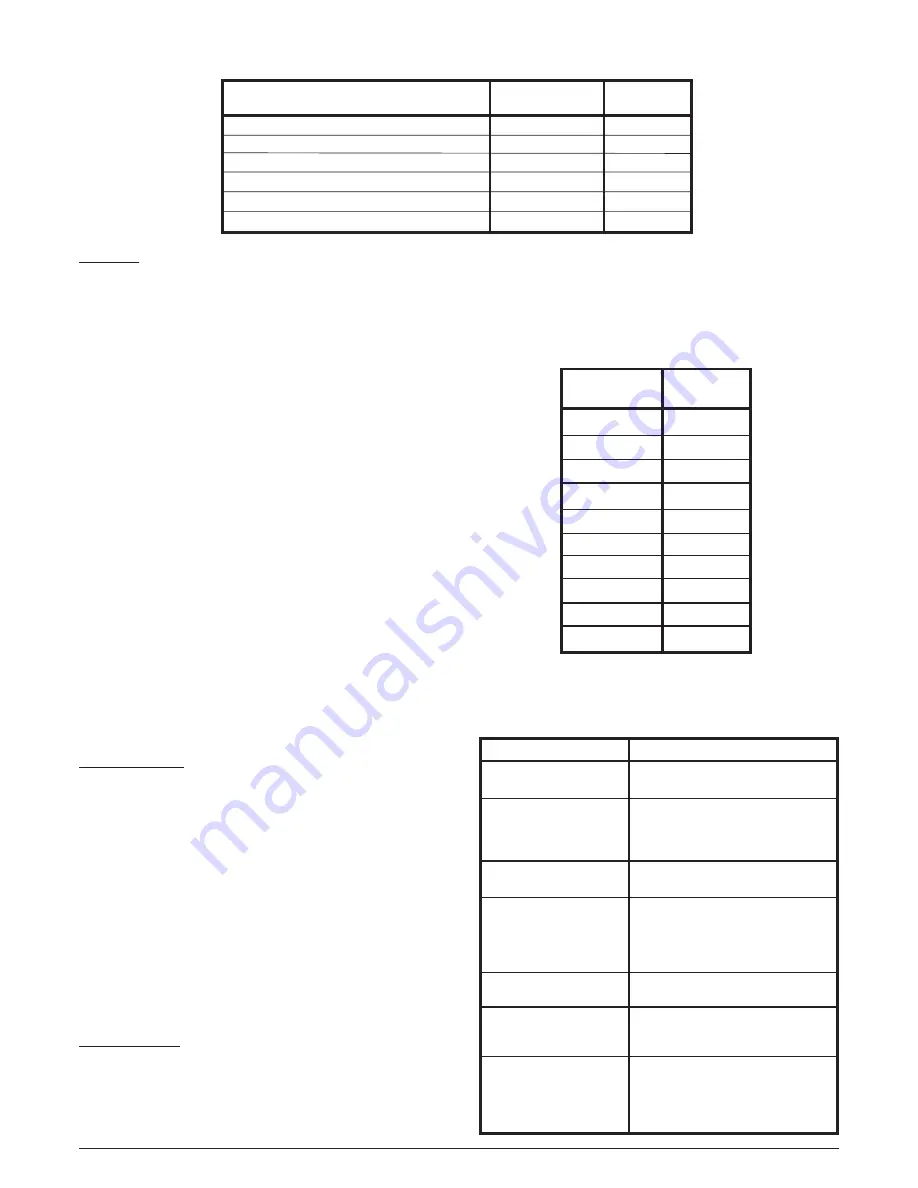

Table 5: Problem Solving

Table 4: A300E Current Consumption

Fan Speed

Current mA

Bargraph Value

0

110

1

120

2

130

3

150

4

170

5

190

6

220

7

235

8

265

9

300

Table 3: Typical Flow Sensitivity Settings

PIPE SETUP

RECOMMENDED

FLOW

(all 50m lengths unless otherwise stated)

FAN SPEEDS

SENSITIVITY

13 x 3mm Sampling Holes, 1 x 6mm End Hole

9

9

8 x 3mm Sampling Holes, 1 x 6mm End Hole

6-9

9

4 x 3mm Sampling Holes, 1 x 6mm End Hole

6-9

7

1 x 5mm Sampling Hole, 1 x 5mm End Hole

6-9

5

1 x 8mm End Hole

5-9

2

1 x 8mm End Hole (10m Pipe)

3-9

1

Problem

Possible Solutions

Power light flashing.

Ensure supply to external power

connector within limits.

No lights on display.

Ensure supply leads correctly

Fan not running

orientated. Ensure that FUSE

correctly seated in socket and fuse

not blown.

No lights on display.

Ensure ribbon cable fully seated into

Fan running OK.

main & display boards.

Flow HI/LO light on

Ensure sampling pipes correctly

installed, lid fitted and box fully sealed.

Ensure filters not blocked.

Ensure flow calibration procedure has

been carried out

Flow reading on Bargraph Decrease Flow sensitivity setting

display moves erratically.

and re-calibrate air flows

Flow reading on

Increase Flow sensitivity setting

Bargraph unresponsive

and re-calibrate air flows

to broken/blocked pipes

Sensor(s) unresponsive

Ensure sampling pipe installed correctly

to smoke tests

and undamaged. Ensure that holes

and pipe length do not exceed limits

for detector. Ensure that

recommended test method is used.