pag.

4

Industrial PC - MONITOR COPILOT 21,5"

Order Code 2E000xxx

May 2018 - Rev. 1.1

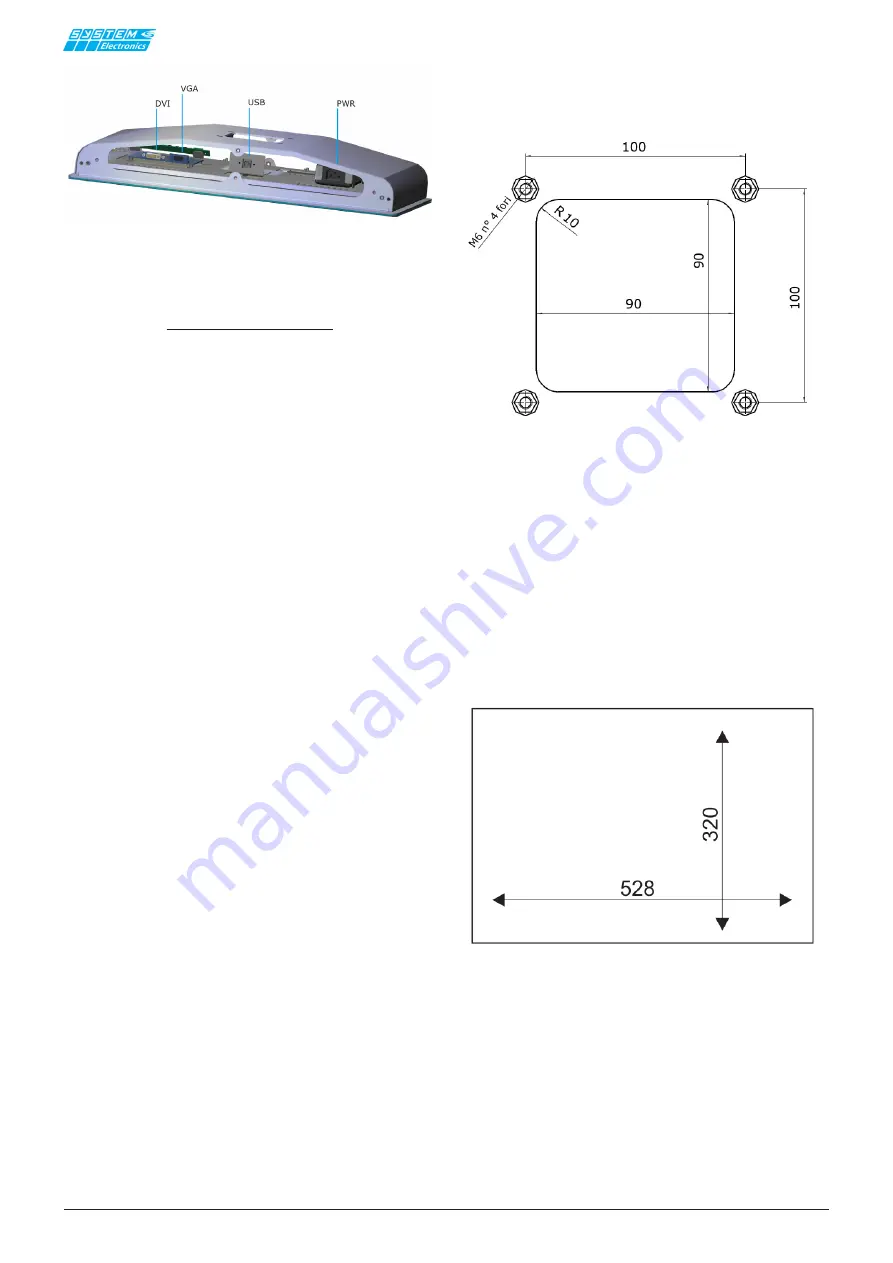

4.2 Installation in the hanging

version (VESA100)

To properly mount the

Copilot 21.5" Monitor

in the

VESA100 arm-mounted version follow the instructions

below:

-

Remove the

Copilot 21.5" Monitor

from its

packaging and place it on a flat surface free of objects,

placing a soft cloth on the table itself to avoid scratching

the glass during installation.

-

Place the

Copilot 21.5" Monitor

with the glass

facing the table. Avoid even momentarily placing the

terminal in a vertical position or slightly leaning against

the mechanism to avoid damage due to the unstable

position.

-

Place the cables that will be connected to the

Copilot 21.5" Monitor

on the fixing arm, making them

protrude about 30cm beyond the fixing point of the arm

itself: cables that will be connected inside the PC itself.

-

Remove the 6 M5 fixing screws of the Monitor

Copilot 21.5" Monitor

that cover the upper and lower

doors, taking care to keep the gaskets placed in the

screws themselves and inside the mechanics, in order

to reassemble them later in the same position.

-

Typically all connection cables are connected

from the bottom of the

Monitor

: the removal of the top

door can facilitate the insertion of the cables allowing

you to control their insertion.

-

Place the

Monitor

on the VESA arm by inserting

all cables inside from the rear center hole.

- The

Copilot 21.5" Monitor

can be attached

to the arm using the M6 screws provided. In case the

screws need to be replaced to fit the used arm, be careful

not to exceed the length of the internal thread by more

than 8mm from the outer edge, to avoid damaging the

internal components.

-

Only then connect the communication cables to

the VESA arm: USB, Ethernet, RS232 are all located on

the bottom side

4.2.1 Size of the opening for cable routing in the 21.5" Copilot

Monitor positioned on the VESA arm.

The

Copilot 21.5'' Monitor

can be installed in the

recessed or wall mounted version, prepared to be con-

nected to a VESA100 arm.

-

Close the covers taking care to reposition the

insulating gaskets and screw O-rings (for models with

IP67 protection).

It is possible to adjust and tighten the VESA100 joint

of the

Copilot 21.5'' Monitor

(available as an option)

using a normal grinder key (cod. 90006195).

4.3 Panel mounting

-

Drilling the panel according to the dimensions

indicated: 320 x 528

4.3.1 Panel drilling jig

-

Remove the

Copilot 21.5" Monitor

from its

packaging and place it on a flat surface free of objects,

placing a soft cloth on the table itself to avoid scratch-

ing the glass during installation. Place the Copilot 21.5"

Monitor with the glass facing the table. Avoid even mo-

mentarily placing the terminal in a vertical position or

slightly leaning against the mechanism to avoid damage

due to the unstable position.

-

Remove the 6 M5 screws that secure the upper

and lower sides.

Figure 4.1.1: Bottom door connectors view.

***