Superiorfireplaces.US.com

126900-01_B

7

CHECKING GAS CONNECTIONS

WARNING: Test all gas piping and connections,

internal and external to unit, for leaks after installing

or servicing. Correct all leaks at once.

WARNING: Never use an open flame to check for a

leak. Apply a noncorrosive leak detection fluid to all joints.

Bubbles forming show a leak. Correct all leaks at once.

PRESSURE TESTING GAS SUPPLY PIPING SYSTEM

Test Pressures In Excess Of 1/2 PSIG (3.5 kPa)

1. Disconnect log set and its individual equipment shutoff valve

from gas supply piping system.

2. Cap off open end of gas pipe where equipment shutoff valve was

connected.

3. Pressurize supply piping system by either using compressed air

or opening main gas valve located on or near gas meter.

4. Check all joints of gas supply piping system. Apply a noncorrosive

leak detection fluid to all joints. Bubbles forming show a leak.

5. Correct all leaks at once.

6. Reconnect log set and equipment shutoff valve to gas supply.

Check reconnected fittings for leaks.

Test Pressures Equal To or Less Than 1/2 PSIG (3.5 kPa)

1. Close equipment shutoff valve (see Figure 5).

2. Pressurize supply piping system by either using compressed air

or opening main gas valve located on or near gas meter.

3. Check all joints from gas meter to equipment shutoff valve (see

Figure 5). Apply a noncorrosive leak detection fluid to all joints.

Bubbles forming show a leak.

4. Correct all leaks at once.

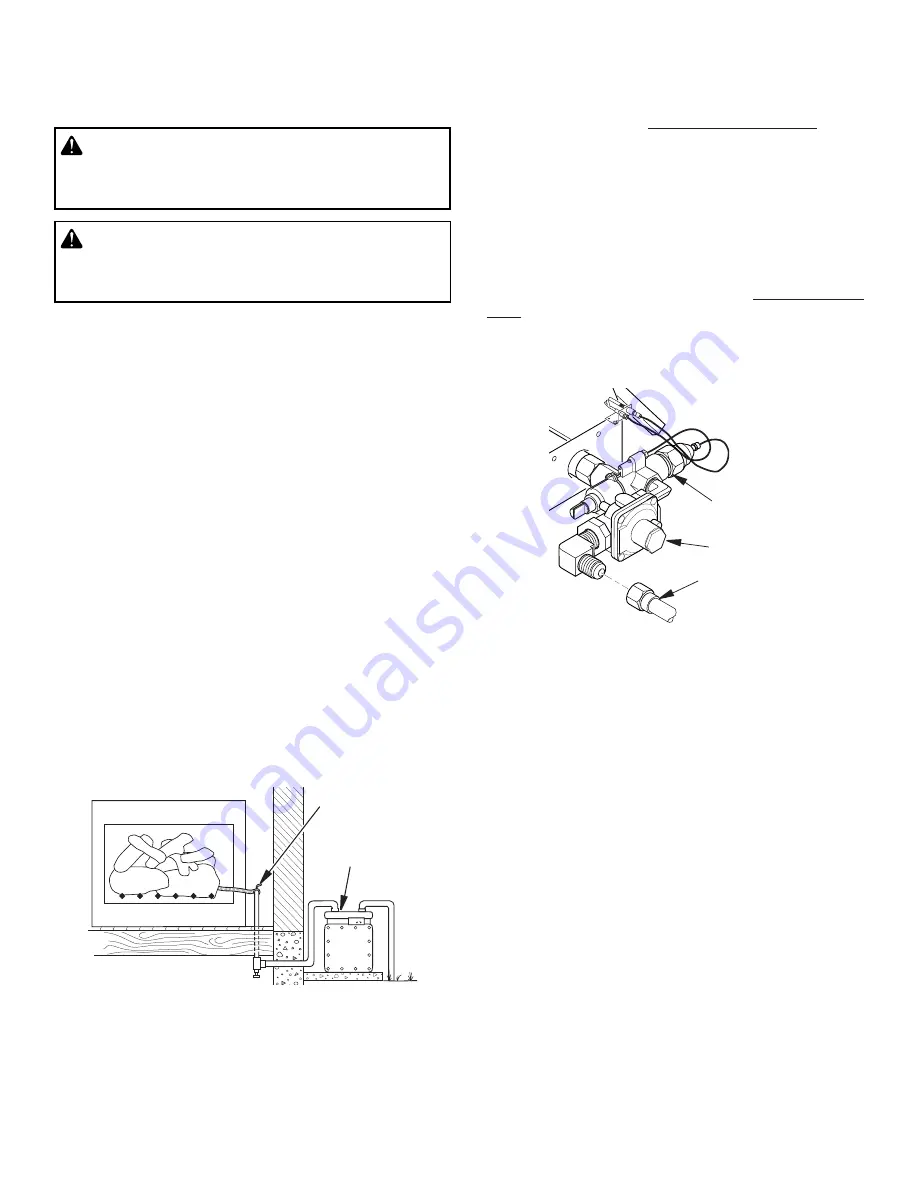

Figure 5 - Checking Gas Joints

Figure 6 - Installing Inlet Fitting and Gas Connector Tube (Valve

Cover Removed for Clarity)

Gas Connector

Tube

Gas Control

Valve

Regulator

INSTALLATION

Continued

HEARTH PAN INSTALLATION

If using propane/LP gas, see

Propane/LP Gas Conversion

, before

installing hearth pan.

1. Place burner pan assembly in center of fireplace floor. Make sure

front of pan faces forward.

2. Thread gas supply fitting to fireplace gas supply pipe. Adjust to

most convenient position.

3. Install gas connector tube to gas supply adapter. Carefully shape

tube and attach to gas inlet fitting (see Figure 6). Be careful not

to cause kinks in tube.

4. Test for leaks following instructions under

Testing Burner for

Leaks

, page 9.

5. Retighten and adjust location of gas control as necessary. Gas

control should be level, with control rod to the front.

Gas Meter

Equipment

Shutoff Valve

Propane/LP Gas Conversion

To convert to propane/LP gas, burner inlet fitting and pilot orifice

must be replaced and regulator pressure must be reset. Propane/LP

burner inlet fitting is supplied with orifice installed. Propane/LP pilot

orifice for converting pilot is supplied and is marked with a red stripe.

1. Remove control rod extension and piezo ignitor by pulling gently.

2. Remove screws that attach pilot assembly to valve cover and

valve cover to burner pan (see Figure 7, page 8).

3. Remove valve cover.

4. Using a wrench, remove gas control valve and burner inlet fitting

by turning counterclockwise (see Figure 8, page 8).

5. Remove burner inlet fitting from gas control assembly (see Figure

8, page 8). DO NOT remove orifice from this fitting. Propane/LP

burner inlet fitting is included in hardware kit (see Figure 9, page

8).

6. Be sure to use correct orifice for your appliance. Orifice kit in-

cluded with this appliance contains an orifice installed in an air

mixer fitting.

7. Using thread sealant (resistant to the action of propane/LP gas)

on smaller end of fitting, screw burner inlet fitting into outlet side

of gas control (see Figure 8, page 8). Tighten using a wrench.