44--77

4.3

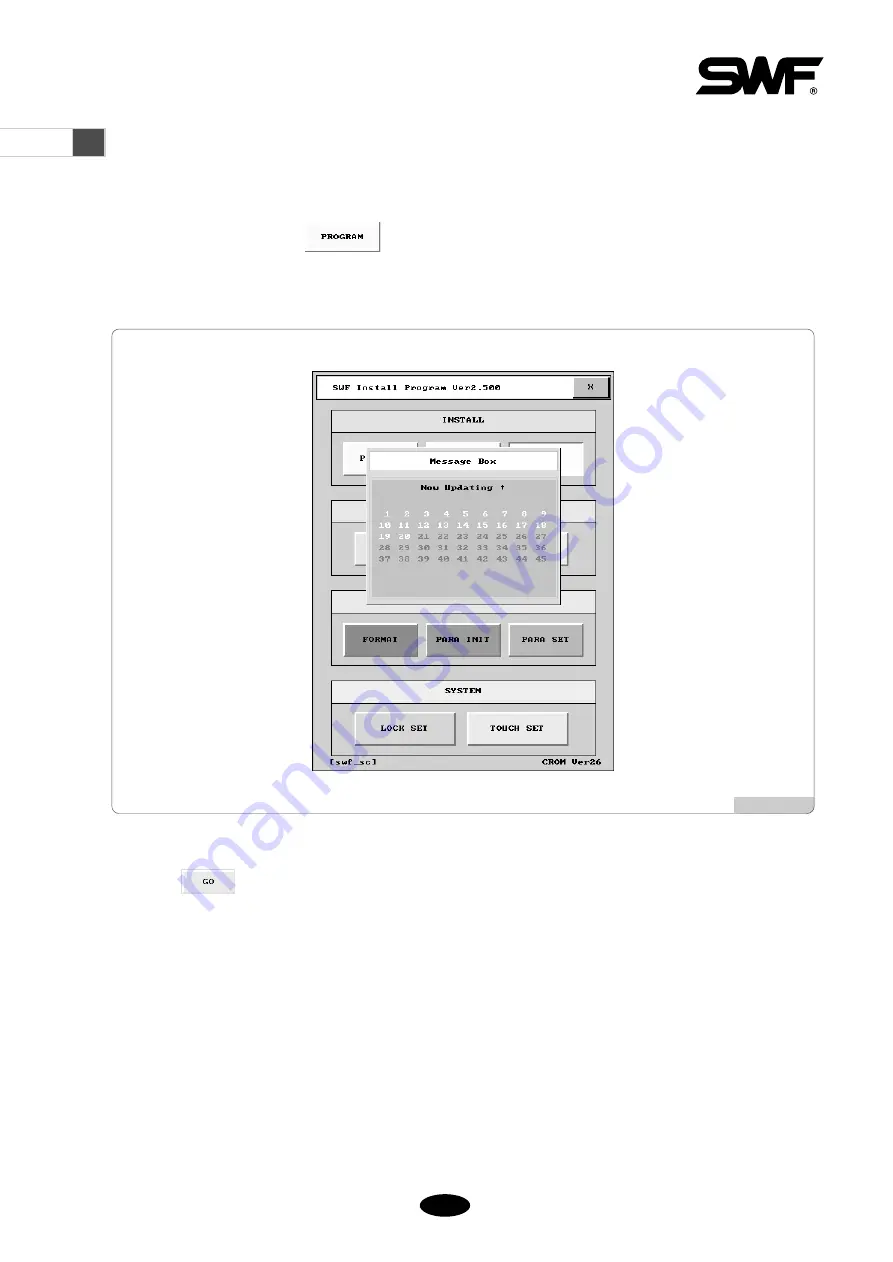

Bootloader of Thread Sensing Board

Upon version upgrading, the software of the thread sensing board should be upgraded following the order below:

①

On the install screen, choose

. The upgraded version in USB (FDD) will be installed.

②

When version upgrade finishes, “Upgrade” message is displayed on the screen as in Fig. 4.3-1.

③

Choose

to start upgrade. Then as in Fig. 4.3-1, the responding IDs are displayed in green, while the non-

responding IDs are displayed in gray.

[Fig.4.3-1]