16E / 16E-H / 16E-P Spray Gun

30

MAN 96150 EN 01

3

Installation

•

See “Technical Data” on page 15 for facility compressed air and

gas requirements.

•

Install and set up all auxiliary equipment in accordance with their

instructions. (See “Auxiliary Equipment” on page 23.)

•

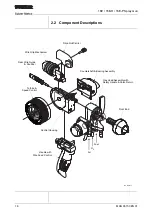

Install, in the spray gun, the hardware required for the spraying

application. Refer to the spray parameters, PAR 96447. See also,

“Hardware Selection” on page 26 and “Maintenance” on page 41.

3.1

Exhaust System

Metal dust, fumes, and the fuel combustion products call for an effec-

tive exhaust and dust collection system. In production installations, if

the spraying station is enclosed, make sure that there is enough open-

ing for inlet air so that the exhaust system is not starved. Under some

conditions, metal dusts can be quite hazardous. For this reason, the

exhaust system should be laid out by an experienced engineer. For

most installations, a dust collector especially designed for metallizing

dust should be installed. Dust collectors designed primarily for other

kinds of dust may be found to be very ineffective and, in some cases,

dangerous, if used for metal dust.

3.2

Wire Control Unit

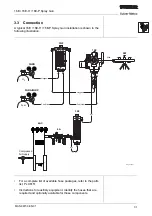

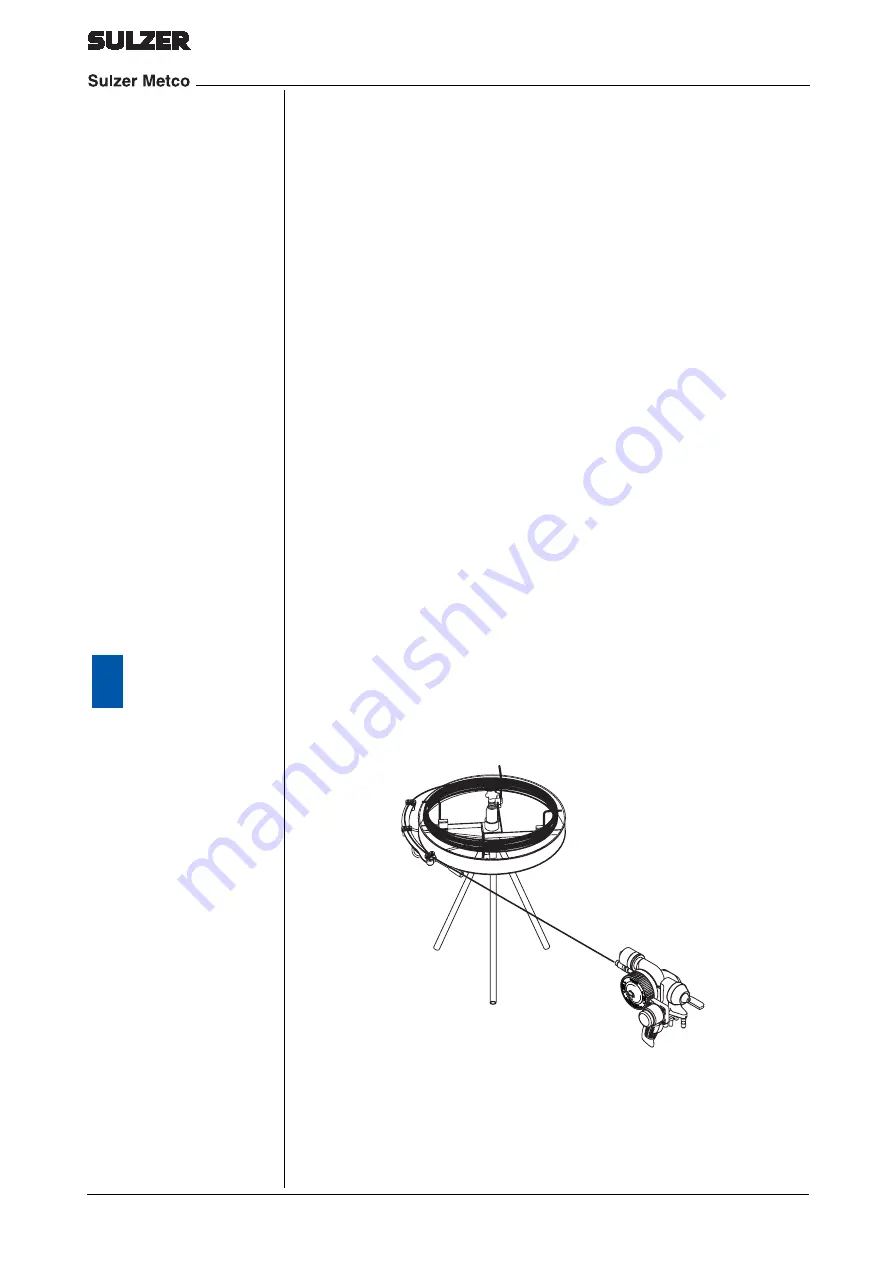

The 2W Wire Control Unit should be located so that the feeding wire is

as straight as possible as it enters the rear wire guide of the spray gun.

If the spray gun is mounted on a stationary tool stand, place the 2W as

close as practical. If the spray gun is to be hand-held or mounted on a

lathe or other manipulating equipment, place the 2W back far enough

to allow the wire to straighten as it feeds.

INFO

Always leave the origi-

nal tag on the wire spool

so that the wire can be

identified.

i

16e_wire_feed