16E / 16E-H / 16E-P Spray Gun

42

MAN 96150 EN 01

rings with Krytox® before reinstalling the nozzle. Wipe any excess

Krytox® off the nozzle.

The bushing inside the nozzle is intended to fit the wire precisely. This

prevents gas leakage and backfire. This bushing is a very durable

alloy that resists fusing with wire metals (i.e., loading). The bushing will

wear over time, requiring that the nozzle be replaced.

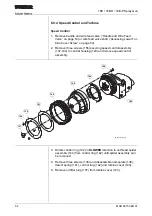

6.4

Gas Head Valve

Proper lubrication of the gas head valve is essential for operation of

the safety handle and for a perfect seal of all gases. The valve core

must always move freely and easily to all positions. If the gas head

valve becomes stiff, fails to close within 1 second of releasing the

safety handle or fails to seal completely, disassemble and clean the

parts of the gas head assembly. Replace all o-rings and apply Kry-

tox®.

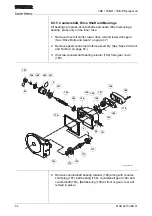

Always remove the hose block and valve plungers before removing

the valve core. One of the hose block mounting screws extends into a

channel in the valve core to prevent the valve core from being

removed while the hose block and valve plungers are installed.

When replacing the o-rings on the valve core, install the o-rings on the

valve core dry. Then, apply a generous amount of Krytox® to the

entire surface of the valve core. After servicing the valve core, purge

the spray gun thoroughly to clear any lubricant from the valve pas-

sages.

The three valve plungers in the hose block have radiused faces to

mate with the curvature of the valve core. The o-rings between the

plungers and valve core are special. They must not be replaced with

non-Sulzer Metco parts. Do not clean these o-rings with solvent. Over

time, these o-rings will become curved and flat and should be

replaced.

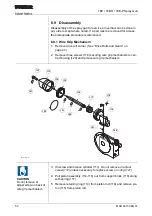

6.5

Countershaft / Bearing Lubrication

To lubricate a dry gun, use no more than 1 fluid oz (30 ml) of Sulzer

Metco Gearlube to fill the gear case. To do this, remove the oil filler

plug from the back of the central housing. Pour in the correct amount

of Gearlube. With the gun upright and level, the lubricant should be

visible at the bottom of the filler plug threads. Check level again after

waiting a short time then install the filler plug and o-ring.

CAUTION

When servicing the gas

head valve, always fol-

low instructions for dis-

assembly under “Gas

Head Assembly” on

page 51 and assembly

under “Gas Head

Assembly” on page 65.