NOTES

24

A pressure relief valve (located on the wet side of the

separator) is set to open if the sump pressure

exceeds the rated pressure of the tank. For added

safety the Supervisor is programmed to shutdown

the package when:

a.

A pressure level, above unload setting but

below relief valve setting, is reached.

b.

A temperature level exceeding 235ºF

(113ºC) is reached.

See Supervisor functional description for further

details on shutdown pressure levels.

The high pressure shutdown protection will shut

down the compressor at 20 psig (1.4 bar) above

rated pressure. This prevents the pressure relief

valve from opening under routine conditions, thereby

preventing fluid loss through the pressure relief

valve. Temperature is monitored via the controller

and will shut down the compressor if the discharge

temperature reaches 235ºF (113ºC).

Fluid is added to the sump via a capped fluid filler

opening, placed low on the tank to prevent overfilling

of the sump. Two sight glasses enable the operator

to visually monitor the sump fluid level.

2.5

CONTROL SYSTEM,

FUNCTIONAL DESCRIPTION

and

purpose of the compressor control system is to

regulate the amount of air being compressed to

match the amount of compressed air being used.

The capacity control system consists of a spiral valve

and an inlet butterfly valve. The functional description

of the control system is described below in 4 distinct

phases of compressor operation. The following

applies to TS32 Series compressors ranging from

400 through 600hp (298-447kw). For explanatory

purposes, this description applies to any compressor

with an operating range of 100 to 110 psig (6.9 to 7.6

bar). A compressor with any other pressure range

would operate in the same manner except for the

stated pressures.

START MODE—0 TO 50 PSIG (0 TO 3.4

BAR)

When the compressor (ON)

pad is

depressed, the sump pressure will quickly rise from 0

to 50 psig (0 to 3.4 bar). During this period, both of

the pressure regulators and the solenoid valve are

closed and the Sullicon Control and spiral valve are

inoperative. The spring on the control holds the

butterfly valve fully open while the spiral valve is fully

closed (maximum) position and the compressor

pumps at full rated capacity. The rising compressor

air pressure is isolated from the service line in this

phase by the minimum pressure valve set at

approximately 50 psig (3.4 bar). An optional closed

inlet system is provided which uses air pressure to

close the butterfly and opens the spiral valve to

reduce motor torque for starting.

FULL LOAD MODE—50 TO 100 PSIG (3.4

TO 6.9 BAR)

50 TO 100 PSIG (3.4 TO 6.9 BAR) When the

compressed air pressure in the sump rises above 50

psig (3.4 bar), the minimum pressure valve opens,

allowing compressed air to flow into the service line.

From this point on, the line air pressure is continually

monitored by the Supervisor. The pressure

regulators and the solenoid valve remain closed

during this phase, keeping the Sullicon Control and

spiral valve inactive. Both the spiral valve as well as

the inlet butterfly valve remain in the full load position

as long as the compressor is running at 100 psig (6.9

bar) or below.

MODULATING MODE—100

TO

110 PSIG

(6.9 TO 7.6 BAR)

100 TO 110 PSIG (6.9 TO 7.6 BAR) As air demand

drops below the rated capacity of the compressor,

the line pressure will rise above 100 psig (6.9 bar).

As a result, the differential pressure regulator for the

spiral valve gradually opens, applying air pressure to

the spiral valve actuator. Air pressure at the actuator

WARNING

DO NOT remove caps, plugs, and/or other

components when compressor is running

or pressurized.

Stop compressor and relieve all internal

pressure before doing so.

NOTE

Always refer to the machine nameplate for

designed operating pressure.

Summary of Contents for TS32 AC

Page 10: ...NOTES 10...

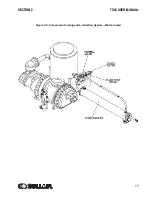

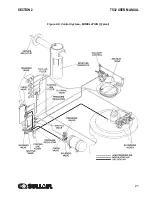

Page 15: ...SECTION 2 TS32 USER MANUAL 15 Figure 2 3 Compressor Piping and Instrument Diagram Typical...

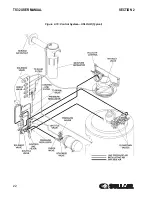

Page 16: ...TS32 USER MANUAL SECTION 2 16 Figure 2 4 Compressor Cooling and Lubrication System Air cooled...

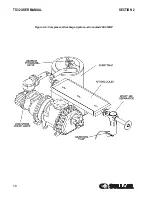

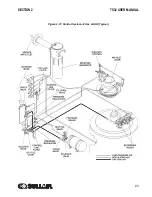

Page 18: ...TS32 USER MANUAL SECTION 2 18 Figure 2 6 Compressor Discharge System Air cooled 200 350HP...

Page 19: ...SECTION 2 TS32 USER MANUAL 19 Figure 2 7 Compressor Discharge System Water cooled 200 350HP...

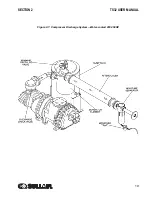

Page 20: ...TS32 USER MANUAL SECTION 2 20 Figure 2 8 Control System START Typical...

Page 21: ...SECTION 2 TS32 USER MANUAL 21 Figure 2 9 Control System MODULATION Typical...

Page 22: ...TS32 USER MANUAL SECTION 2 22 Figure 2 10 Control System UNLOAD Typical...

Page 23: ...SECTION 2 TS32 USER MANUAL 23 Figure 2 11 Control System FULL LOAD Typical...

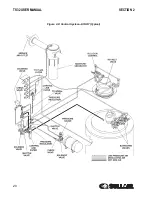

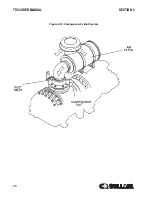

Page 26: ...TS32 USER MANUAL SECTION 2 26 Figure 2 12 Compressor Air Inlet System...

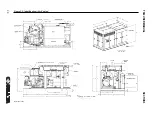

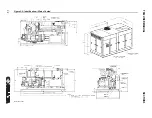

Page 30: ...TS32 USER MANUAL SECTION 3 30 Figure 3 2 Identification Air Cooled 02250126 376 R02...

Page 32: ...TS32 USER MANUAL SECTION 3 32 Figure 3 2 Identification Water Cooled 02250126 378 R03...

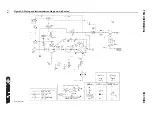

Page 50: ...TS32 USER MANUAL SECTION 3 50 Figure 3 9 Wiring Diagram Air Cooled SSRV 02250178 844 R03...

Page 54: ...NOTES 54...

Page 78: ...NOTES 78...

Page 79: ...NOTES 79...