TS32 USER MANUAL

SECTION 4

56

W

ATER

-C

OOLED

C

OMPRESSORS

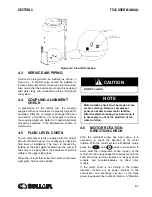

• Water-cooled compressors require a cool-

ing water supply delivered at a constant

rate and volume. (See

. The table data applies

to full load operation using an aftercooler.)

• Compressor water input and return lines

must be sized as a minimum to match the

compressor water connection size, and

have isolation valves with side drains. The

input water line should have a 2mm

strainer installed in-line. A solenoid valve

(normally closed), controlled by the com-

pressor control circuit, should be con-

nected to the compressor’s water outlet.

(Contact Sullair Customer Care for assis-

tance.)

• Cooling water quality is a critical factor

effecting proper machine cooling. Exces-

sive deposit build-ups, such as lime or

scale, restrict the water flow and act as

thermal insulators. These deposits can

increase the compressor’s operating tem-

perature by reducing the cooling system’s

efficiency.

• Regularly inspect and clean all water piping

and coolers.

•

Table 4-2:Ventilation Requirements

speci-

fies the minimum ventilation required for

compressor operation at normal tempera-

tures. The fan air requirement applies to

the volume of air that must pass though the

compressor to ensure proper ventilation.

The heat rejection requirement applies the

amount of heat generated by the compres-

sor which must be removed to maintain a

normal operating temperature.

• If the compressor has a water regulating

valve, it can be used to adjust the compres-

sor temperature to maintain a minimum of

185°F (82.2°C); 195°F (87.8°C) for 24 KT

machines.

• Temperature and pressure gauges should

be installed for water system troubleshoot-

ing.

NOTE

Systems using both reciprocating and

rotary screw compressors must isolate

the two types from each other through the

use of a common receiver tank. Air lines

from each individual compressor should

be connected directly to the common

receiver tank.

NOTE

The “waste heat” from air-cooled com-

pressors can be used for local space

heating. If it is used for this purpose, the

additional static pressure drop across the

fan should not exceed 0.2 in. H

2

0. The

high static fan option is required if duct-

work is added. Contact Sullair Customer

Care for additional information.

NOTE

Housing the compressor in an inade-

quately ventilated enclosure will cause

higher compressor operating tempera-

tures.

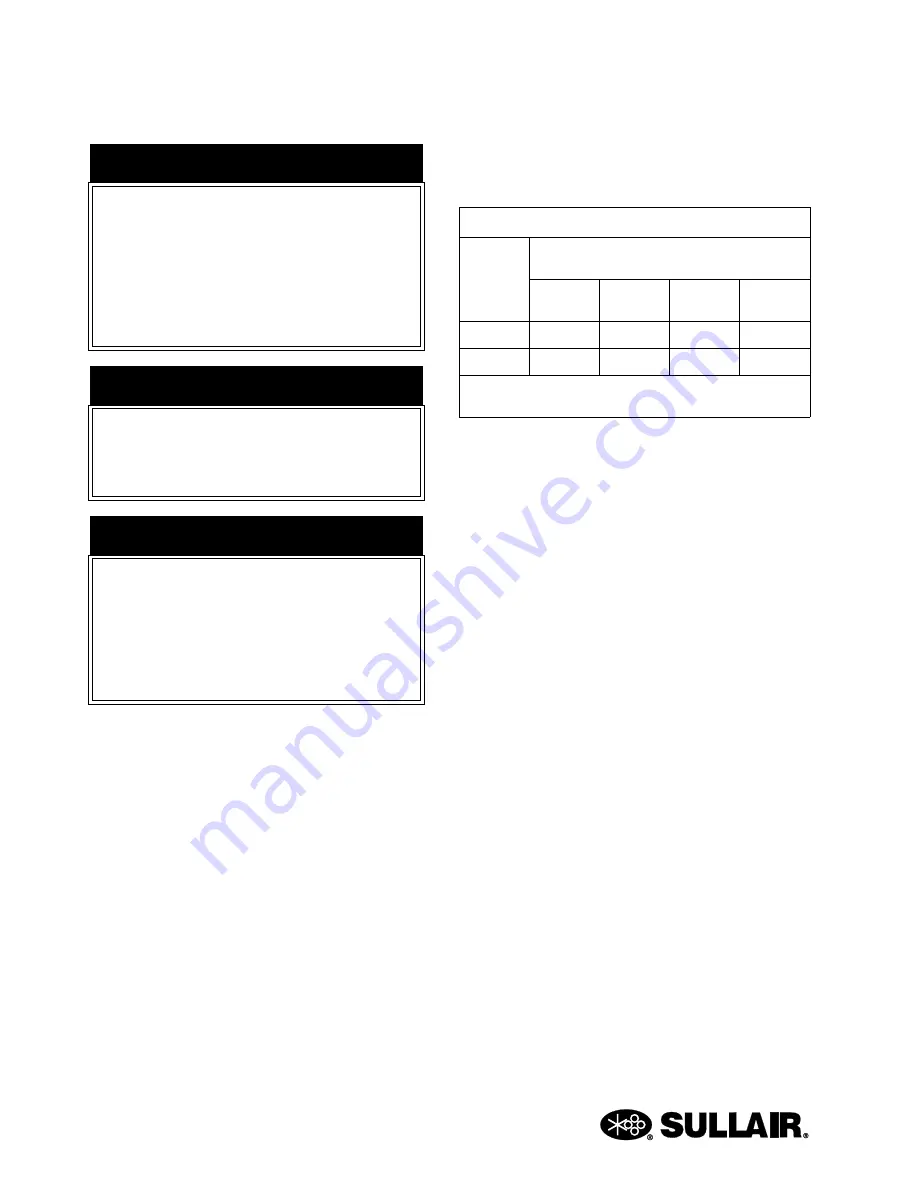

Table 4-1: Water Flow Requirements

Water

Temp °F/

°C

Water Flow

Gallons Per Minute /Liters Per Minute (I)

200HP/

150KW

250HP/

187KW

300HP/

225KW

350HP/

260KW

70/21

36/136

43/163

52/196

61/231

80/27

45/170

54/204

65/246

76/288

(I)

Water pressure should be maintained between 25 and 75

psig (1.7 and 5.2 bar), but not to exceed 145 psig (10 bar).

Summary of Contents for TS32 AC

Page 10: ...NOTES 10...

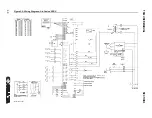

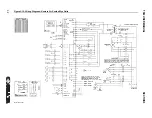

Page 15: ...SECTION 2 TS32 USER MANUAL 15 Figure 2 3 Compressor Piping and Instrument Diagram Typical...

Page 16: ...TS32 USER MANUAL SECTION 2 16 Figure 2 4 Compressor Cooling and Lubrication System Air cooled...

Page 18: ...TS32 USER MANUAL SECTION 2 18 Figure 2 6 Compressor Discharge System Air cooled 200 350HP...

Page 19: ...SECTION 2 TS32 USER MANUAL 19 Figure 2 7 Compressor Discharge System Water cooled 200 350HP...

Page 20: ...TS32 USER MANUAL SECTION 2 20 Figure 2 8 Control System START Typical...

Page 21: ...SECTION 2 TS32 USER MANUAL 21 Figure 2 9 Control System MODULATION Typical...

Page 22: ...TS32 USER MANUAL SECTION 2 22 Figure 2 10 Control System UNLOAD Typical...

Page 23: ...SECTION 2 TS32 USER MANUAL 23 Figure 2 11 Control System FULL LOAD Typical...

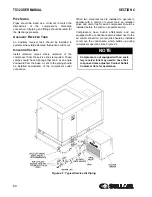

Page 26: ...TS32 USER MANUAL SECTION 2 26 Figure 2 12 Compressor Air Inlet System...

Page 30: ...TS32 USER MANUAL SECTION 3 30 Figure 3 2 Identification Air Cooled 02250126 376 R02...

Page 32: ...TS32 USER MANUAL SECTION 3 32 Figure 3 2 Identification Water Cooled 02250126 378 R03...

Page 50: ...TS32 USER MANUAL SECTION 3 50 Figure 3 9 Wiring Diagram Air Cooled SSRV 02250178 844 R03...

Page 54: ...NOTES 54...

Page 78: ...NOTES 78...

Page 79: ...NOTES 79...