To prevent disturbances it is necessary to

carry out the prescribed maintenance and

inspection measures regularly. Changes with

regard to normal operation (higher power

consumption, temperatures or fluctuations,

unusual noises or smells, actuation of

monitoring

devices

etc.)

indicate

that

functioning is impaired.

To avoid disturbances which could cause

severe

personal

injury

or

damage

to

property,

the

maintenance

personnel

responsible must be informed immediately.

In case of doubt, disconnect and secure the

appropriate equipment immediately.

8. Spare Parts and Repair

Spare parts must comply with the technical

requirements specified by the manufacturer.

This is always guaranteed with original spare

parts.

When

ordering

spare

parts,

quote

the

designation, the part number of

spare part

drawing), the type number

and the serial

number (see name-plate or technical data).

Spare part drawings and parts lists see pages

16-19.

Repairs and overhauls are carried out by Stiebel

without delay.

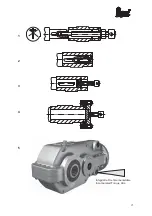

Disassembly of the Gears

Dismantle cover seal, hexagon head cap screw,

disk and, where applicable, the retaining ring or

shrinking disk. In exactly the same way as when

tightening the shrinking disk bolts, these must

also be unscrewed evenly in several stages to

prevent the disks from tilting.

Hollow shaft keyway: insert a disk of the

appropriate diameter with thread into the hollow

shaft. Fasten the disk using the retaining ring.

Then press back the gear with a threaded

spindle against the shaft end, ensuring that the

centre hole is protected against damage (see fig.

3, page 21).

Hollow shaft shrinking disk: fit a ring onto the

shaft collar and fasten it with a retaining ring. A

disk with a threaded bore hole is screwed onto

this ring and the threaded spindle is inserted into

this hole to maintain pressure (see fig. 4, page 21).

Stiebel is not responsible for damages resulting

from

inappropriate

repair

or

the

use

of

non-original spare parts.

When carrying out repairs yourself, it must be

ensured that working and auxiliary materials and

replaced parts are disposed of safely and

without damaging the environment.

Prolonged contact with lubricants can cause

damage to the skin. Use protective skin

ointment. After prolonged operation, the

lubricant and the surface of gearboxes can

reach temperatures which can burn the skin.

Let

the

gear

unit

cool

down

before

commencing repair work.

During disassembly, it must be ensured that the

gear does not tilt on the shaft, i.e. it must be

secured in good time with appropriate lifting

equipment.

The applicable national, local and plant-specific

conditions and requirements concerning the

prevention of accidents must be observed.

14