24

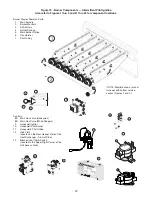

TABLE 7 - MAIN BURNER ORIFICE SCHEDULE*

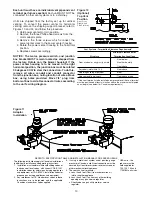

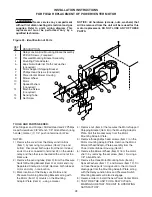

PRIMARY AIR SHUTTER ADJUSTMENT

After the unit has been operating for at least 15 minutes,

adjust the primary air flow to the burners. Turn the

friction-locked, manually-rotated air shutters clockwise

to close, or counterclockwise to open.

For correct air adjustment, close the air shutter until yellow

tips in the flame appear. Then open the air shutter to the

point just beyond the position where yellow tipping

disappears. Refer to Figure 20.

NOTICE: There may be momentary and spasmodic

orange flashes in the flame. This is caused by the

burning of airborne dust particles, and not to be

confused with the yellow tipping, which is a stable or

permanent situation when there is insufficient

primary air.

Figure 20 - Main Burner Flames

GAS INPUT RATE

Never overfire the duct furnace, as

this may cause unsatisfactory operation or shorten

the life of the heater.

Check the gas input rate as follows (Refer to general

safety section for metric conversions/SI units):

1.

Turn off all gas appliances that use gas through the

same meter as the heater.

2.

Turn gas on to the heater.

3.

Clock the time in seconds required to burn one cubic

foot of gas by checking the gas meter.

4.

Insert the time required to burn one cubic foot of

gas into the following formula and compute the

input rate.

3600 (Sec. Per Hr.) x Btu/Cu. Ft

= Input Rate

Time (Sec.)

For example, assume the Btu content of one cubic foot of

gas equalled 1000 and that it takes 18 seconds to burn

one cubic foot of gas.

3600 x 1000

= 200,000

18

NOTICE: If the computation exceeds or is less than

95 percent of the gas Btu/hr. input rating (see

“Specifications”), adjust the gas pressure.

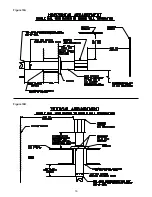

Adjust the gas pressure as follows:

1.

NATURAL GAS: Best results are obtained when the

heater is operating at its full input rating with the

manifold pressure of 3.5 inches W.C. (0.9 kPa).

Adjustment of the pressure regulator is not normally

necessary since it is preset at the factory.

However, field adjustment may be made as follows:

a.

Attach manometer at pressure tap plug

adjacent to control outlet.

b.

Remove regulator adjustment screw cap,

located on combination gas valve.

c. With a small screwdriver, rotate the adjustment

screw counterclockwise to decrease or clock-

wise to increase pressure. Do not force beyond

stop limits.

d. Replace regulator adjustment screw cap.

2.

PROPANE GAS: An exact manifold pressure of

10.0 inches WC (2.5 kPa) must be maintained for

proper operation of the heater. If the unit is equipped

with a pressure regulator on the combination gas

valve, follow steps “a” through “d” above. If the unit

is not so equipped, the propane gas supply system

pressure must be regulated to attain this manifold

operating pressure.

FT

3

/HR

ORIFICE DRILL

FT

3

/HR

ORIFICE DRILL

FT

3

/HR

ORIFICE DRILL

*

INPUT

IN

1000

BTU

NO. OF

BURNER

ORIFICES

3.5" W.C.

(0.9 kPa)

1

0.0" W.C.

(2.5 kPa)

MANIFOLD

PRESSURE

PROPANE

TYPE OF GAS

NATURAL

2500 BTU/Ft

3

(93.1 MJ/m

3

)

1075 BTU/Ft

3

(40.1 MJ/m

3

)

HEATING

VALUE

100

125

150

175

200

225

250

300

350

400

4

5

6

7

8

9

10

12

14

16

96

42

120

42

140

42

163

42

186

42

210

42

233

42

280

42

326

42

372

42

40

54

50

54

60

54

70

54

80

54

90

54

100

54

120

54

140

54

160

54

FT

3

/HR

ORIFICE DRILL

FT

3

/HR

ORIFICE DRILL

FT

3

/HR

ORIFICE DRILL

FT

3

/HR

ORIFICE DRILL

FT

3

/HR

ORIFICE DRILL

FT

3

/HR

ORIFICE DRILL

FT

3

/HR

ORIFICE DRILL

* This schedule is for units operating at normal altitudes of 2000 ft. (610m) or

less. SPECIAL ORIFICES ARE REQUIRED FOR INSTALLATIONS ABOVE

2000 FEET (610M).

When installed in Canada, any references to deration at altitudes in excess of

2000 feet (610m) are to be ignored. At altitudes of 2000 to 4500 feet (610 to

1372m), the unit heaters must be orificed to 90% of the normal altitude rating,

and be so marked in accordance with the CSA certification.

LIFTING

(TOO MUCH AIR)

YELLOW TIPPING

(MARGINAL)

NORMAL

(HARD FLAME)

YELLOW FLAME

(TOO LITTLE AIR)

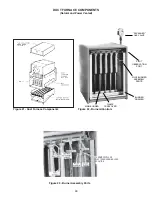

Summary of Contents for NATURAL INDOOR GAS-FIRED DUCT FURNACE

Page 14: ...14 Figure 12A Figure 12B...

Page 15: ...15 Figure 13A Figure 13B...

Page 34: ...34 NOTES...

Page 36: ......