13

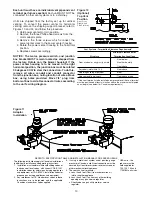

Each unit must have an individual vent pipe and vent

terminal per furnace section!

Each unit MUST NOT be

connected to other vent systems or to a chimney.

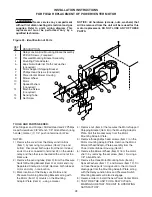

Units are shipped from the factory set up for vertical

venting. To convert the power venter for horizontal

venting, remove the shipping support bracket; refer to

Figures 10 and 24, and follow this procedure:

1. Hold power venter motor in position.

2. Remove the three Phillips-head screws from the

motor adaptor plate.

3. Remove the three screws which connect the

power venter stack to the power venter housing.

4. Rotate the power venter housing to the horizontal

position.

5. Replace screws accordingly.

NOTICE: The motor, pressure switch, and junction

box bracket MUST remain located as shipped from

the factory. Rotate only the blower housing! If the

power venter housing is to be moved to the right

horizontal position, the junction box must be rotated

90 degrees CCW to clear the connection. To do this,

remove all wires, conduit and conduit connector

from the junction box, noting location of wires. Move

box, using holes provided. Move 7/8" plug from

bottom of box to side. Reconnect all wires according

to the unit’s wiring diagram.

Figure 11

Adaptor

Installation

Figure 10

(Optional)

Top Vent

Position

Rear, Front,

Right & Left

Flue Positions

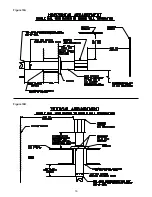

Vent Systems - Termination Clearance Requirements*

Minimum Clearances for

Structure

Termination Locations

4 feet below

Door, window or any gravity air inlet

4 feet horizontally

1 foot above

Forced air inlet within 10 ft.

3 feet above

Adjoining building or parapet

6 feet

Adjacent public walkways

7 feet above grade

*If the vent terminal is to be installed near ground level, the vent terminal

must be positioned at least six inches above the maximum anticipated

snow depth (see below for Canadian requirements)

REFER TO SPECIFICATION TABLE AND INSTALLATION MANUAL FOR PROPER USAGE

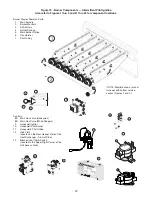

The following instructions apply to Canadian installations

in addition to installation and operating instructions:

1. Installation must conform with local building codes, or

in absence of local codes, with current CGA B149.1

installation codes for natural gas burning appliances

and equipment, or CGA B149.2, installation codes for

propane gas burning appliances and equipment.

2. Any references to U.S. standards or codes in these

instructions are to be ignored and the applicable

Canadian standards or codes applied.

3. If using a metal vent system under positive gauge

pressure in Canada, a slip fit vent connection must be

secured by at least two corrosion-resistant screws, or

other mechanical locking means.

4. The vent shall not terminate -

a. Less than 6 feet (1.8m) from a combustion air

inlet or another appliance.

b. Less than 3 feet (1m) from any other building

opening or any gas service regulator.

c. Directly above a gas utility meter or service

regulator.

* USA units - the

reducer must be

field supplied for

100, 125, 150 and

175 MBH unit sizes.

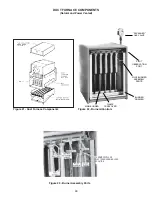

Summary of Contents for NATURAL INDOOR GAS-FIRED DUCT FURNACE

Page 14: ...14 Figure 12A Figure 12B...

Page 15: ...15 Figure 13A Figure 13B...

Page 34: ...34 NOTES...

Page 36: ......