12

During the heating season, a constant

volume of water must be maintained inside

the heating system. When topping up water,

care must be taken that no air is sucked into

the system. Water must never be let out of

the boiler or the heating system, unless it is

absolutely essential, such as before repairs,

etc. Draining water and refilling the system

ial, such as before repairs, etc with new water

increases the risk of corrosion and formation

of incrustation.

Please note

Filling or topping up water to the heating

system must always be done with the boiler

cold or cooled down; otherwise the boiler

block may crack!

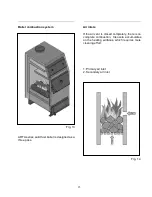

Operation and controls

Starting a fire

Check on the thermometer whether there is

enough water in the heating system. Open

the shutting valve between the boiler and the

heating system. Spread paper on top of the

clean stoker and then enough finely chopped

wood. Open the flue flap in the chimney

adapter and shut the stoking door. Light the

paper through the open ashtray door and fully

open the regulating flap in the ashtray door.

The fire has caught up enough stoke a layer

of main fuel on top of the burning firewood.

When the fire is powerful enough, stoke more

fuel right up to the bottom edge of the stoking

door and level it into.

Provide an even layer throughout the entire

boiler depth. If the fuel suddenly turns into

dark red blaze, open partially the secondary

air supply rosette in the stoking door. When

the flame turns yellow, shut the secondary air

supply rosette again. When the boiler has

reached the required output, it is suitable to

partially shut the flue thrust flap to prevent

heat from unnecessarily escaping into the

chimney.

•

Do not start the boiler without connecting

the boiler to the chimney.

•

Control

chimney

connections

before

starting the boiler.

•

Adjust the chimney blow as requested level.

If chimney blow is under mentioned levels

try not to use the boiler.

Setting the outlet water temperature

When the required outlet water temperature is

say 60 °C, heat up the boiler to a temperature

for instance 5 °C higher than the required

temperature of 60 °C (measured on the

thermometer on the boiler outlet pipe). Then

turn the control knob to 65 °C and check

whether the chain is stretched and the

regulating hatch completely shut. This position

of the chain and regulating hatch is fine-

adjusted y turning the control knob. Then let

the regulation process work. When the water

temperature drops, the regulating hatch will

start opening by the tension applied by the

regulator on the chain. When the water

temperature suddenly rises, the regulating

hatch will start opening. And the hot water

temperature on the boiler outlet is controlled.

Stoking

First shut the regulating hatch; this will shut

supply of combustion air into the boiler. Then

open the chimney flap completely. Partially

open the stoking door and wait until all

combustion gases have been sucked from

the combustion chamber into the chimney.

Summary of Contents for ARTA series

Page 1: ...REV 01 2012 122088 ...

Page 5: ...5 Boiler dimensions ...

Page 6: ...6 Boiler packaging ...

Page 7: ...7 Technical parameters ...

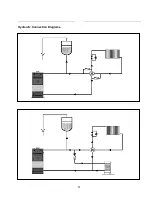

Page 22: ...22 Hydraulic Connection Diagrams ...

Page 24: ...24 ARTA boiler parts ...

Page 25: ...25 ARTA boiler spare parts lists ...

Page 26: ...26 ...

Page 27: ...27 Troubleshooting ...

Page 28: ...28 NOTES ...