13

Only then open the stoking door completely

and start stoking the boiler. After shutting the

stoking door, set the chimney flap again and

restore the functioning of the regulating

hatch.

•

Boiler doors must not be held open as the

boiler is continuously working.

•

Provide a minimum 5 cm gap to be

between top point of the fuel and ceiling of

stoking chamber when boiler is stoked.

Overnight heating mode

This mode is used when you want to maintain

the fire in the boiler for instance over night.

First scrape all ash out of the combustion

chamber, with the chimney flap completely

opened. Then stoke the boiler with fuel and

shut the boiler up completely. Then shut the

chimney flap and also almost shut the

regulating hatch. This will reduce the chimney

thrust and restrict the supply of combustion

air. Shut also the secondary air supply

rosette in the stoking door. To restore the

boiler’s required output, just open the

chimney flap and partially open the regulating

hatch to the required boiler output.

Removing solid combustion residuals

Removing and emptying the ashtray situated

underneath

the

stoker

in

the

ash

compartment do this. This must be done on a

regular

basis

to

prevent

ash

from

accumulating and blocking the supply of air to

the combustion chamber from underneath the

stoker.

Dewing and tarring

When starting fire in a cold boiler, water

condensates on the walls and runs down into

the ash compartment, which may make an

impression that the boiler is leaking. This

dewing will disappear after the astray has

settled on the boilers inside walls. When

running the boiler with low water temperature

usually below 65 °C, or when using damp fuel,

water condensates in combustion gases and

the condensate runs down the boiler’s cold

walls. Low temperature heating also reduces

the chimney life. Therefore it is recommended

to equip the boiler with for instance a four-way

blending valve which will ensure that the

temperature of return water does not drop

below 50°C. Boiler tarring occurs under similar

conditions (back of combustion air, the boiler

is choking). To prevent dewing and tarring, we

recommend you run the boiler at temperatures

higher than 65 °C and choose a boiler to

match the required heating system output. An

oversized

boiler

suffers

unnecessarily,

because it has to be run at low temperatures.

Boiler shutdown

We do not recommend that you try to speed

up the boiler combustion process. The fuel

must burn completely on its own on the stoker.

Short term shutdown

After shutting the boiler down, clean it, remove

all combustion residuals, empty the ashtray,

clean the stoking door contact surfaces and

the ash compartment, and then shut the

boiler’s stoking door and ash compartment

door.

Summary of Contents for ARTA series

Page 1: ...REV 01 2012 122088 ...

Page 5: ...5 Boiler dimensions ...

Page 6: ...6 Boiler packaging ...

Page 7: ...7 Technical parameters ...

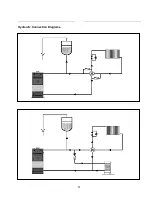

Page 22: ...22 Hydraulic Connection Diagrams ...

Page 24: ...24 ARTA boiler parts ...

Page 25: ...25 ARTA boiler spare parts lists ...

Page 26: ...26 ...

Page 27: ...27 Troubleshooting ...

Page 28: ...28 NOTES ...