11

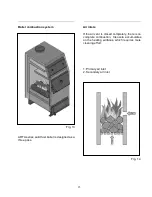

Air rosette

Supply of secondary combustion air is

controlled by an air rosette situated in the

boiler’s stoking door, which has a direct effect

on the level of emission.

Fig. 03

Thermometer

Hot water temperature can be checked on a

thermometer, which is situated in the upper

side boiler cover.

Fig. 04

Putting the boiler into service

Checking the boiler before turning it on

Before putting the boiler into operation, the

service technician must check:

Whether the installation conforms to the

design.

Whether the boiler has been filled in and is

under pressure (on the thermometer), and

whether there are any leakage in the heating

system;

Connection to the chimney - connection must

be approved by an authorised chimney sweep

(chimney inspection);

Functioning of the heating controls.

Please note

The service technician must show the user

how to control the boiler and enter the date

when the boiler was put into service into the

warranty certificate.

Filling up and draining the heating system

The system can only been filled up or topped

up with water which meets the parameters

specified by EN standards. The water must be

clear, colourless, free of suspended particles,

oil and chemically corrosive substances, and

must not be acidic (

P

H factor must be

greater than 7.2 ). First of all, the heating

system must be thoroughly flushed and all dirt

washed out.

Please note

Water in system must not be reduced or put

out unless the boiler is in service or under

freezing danger. Against freezing anti-freeze

liquid can be added in to system water at the

rate of % 15.

Please note

The failure to meet this requirement may lead

to the heat exchanger getting clogged up, and

the steel block may crack as a result.

Summary of Contents for ARTA series

Page 1: ...REV 01 2012 122088 ...

Page 5: ...5 Boiler dimensions ...

Page 6: ...6 Boiler packaging ...

Page 7: ...7 Technical parameters ...

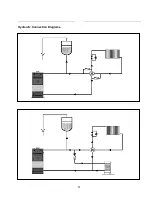

Page 22: ...22 Hydraulic Connection Diagrams ...

Page 24: ...24 ARTA boiler parts ...

Page 25: ...25 ARTA boiler spare parts lists ...

Page 26: ...26 ...

Page 27: ...27 Troubleshooting ...

Page 28: ...28 NOTES ...