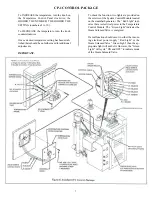

CP-1 CONTROL PACKAGE

CP-1 CONTROL PACKAGE INSTALLATION

AND OPERATION

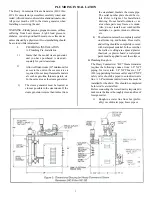

The CP-I Control Package is completely automatic in

operation... room temperature is thermostatically con-

trolled by the Steamist ST-200C Solid State Temperature

Control System in conjunction with the generator’s steam

solenoid valve. No attendant required... set it, forget it.

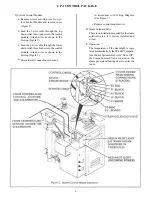

The “rapid response” ST-200C Temperature Control Sys-

tem is made up of three components: Temperature Sensor

Probe (Figure 3), Temperature Control Panel (Figure 4),

and System Control Module (Figure 5). After installation

of the ST200C is complete the steamroorn temperature

will automatically be maintained within 1-1/2 F of the

desired setting.

NOTE:

This control is not an ON/OFF switch, it is used

in conjunction with the Steam Solenoid Valve. The steam

generator cannot be turned OFF with this device.

A. Pre - Construction Considerations

Choose a location to mount the Temperature Con-

trol Panel. If only a manager or limited group will

be in charge of controlling the steambath tempera-

ture, a utility area may be appropriate.

If steambathers will be permitted to adjust the tem-

perature, choose a convenient location outside the

steamroom door.

Mount the Temperature Control Panel OUTSIDE

the steamroom. Mount the Temperature Sensor

Probe INSIDE the steamroom.

WARNING:

All electrical power to the steam gen-

erator

MUST

be turned

OFF

before proceeding

with installation.

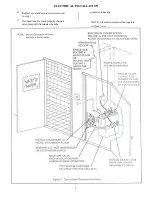

B. CP-1 Control Package Rough-in

The 3 wire cable for Temperature Control Panel to

be used during installation of the ST200C Solid

State Temperature Control System is low voltage;

18 or 22 AWG wire recommended. Every attempt

should be made to match the color wire of the Tem-

perature Control Potentiometer lead wires (P1

white, P2 black, and P3 red) to the 3 wire cable.

Install a metal two-gang switch box rotated 90

(refer to Figure 4). Install an inverted strain re-

lief clamp and feed the 3 wire cable into the

two -gang box. Run the 3 wire came from the

switch box to the steam generator’s location.

1)

STEPS TO INSTALL SENSOR

SEPARATE TWO WIRES OF CABLE (COMING THRU

WALL FROM GENERATORS ST 200C CIRCUIT

BOARD, TERMINAL #2 AND #4) APPROX. 2", STRIP

AND TWIST APPROX. 1/2" OF BARE WIRE.

TAKE NEW SENSOR ASSEMBLY AND TWIST WIRES

TO WALL CABLE AND SECURE WITH WIRE NUTS.

PEEL OFF ADHESIVE BACKING FROM SENSOR.

CAREFULLY APPLY SILICONE SEALANT AROUND

REAR EDGE.

FEED WIRES BACK INTO WALL AND PRESS SENSOR

FIRMLY TO WALL (BE CAREFUL TO ALIGN PLATE

HOLES WITH ANCHOR HOLES).

INSTALL SCREWS, AND SNAP CHROME COVER BACK

IN PLACE.

TEMPERATURE SENSOR ASSEMBLY MUST FORM A

100% WATER TIGHT SEAL TO THE WALL USING SILI-

CONE SUPPLIED.

1)

2)

3)

4)

5)

6)

7)

Note: Location of sensor is as follows:

a) Single tier seating - 6 feet above floor.

b) Double tier seating - 7 feet above floor.

III

4

Summary of Contents for HC-10

Page 1: ...HEAVY COMMERCIAL STEAMBATH GENERATOR OWNERS MANUAL Models HC 9 Thru HC 18 3 98 Pub No 400 G ...

Page 12: ......

Page 13: ......

Page 14: ......