ELECTRICAL INSTALLATION

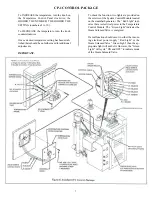

copper tubing is recommended. A shut-

off valve should be convenicnitly placed

in the water feed line.

Rough- in the steam line using 1/2" NPT

brass pipe or 3/4 " I. D. copper tubing. Do

not use iron pipe. it will rust and discolor

wall of steamroom. For a steam line that

is longer than 10 feet, insulation must be

used. The stearnhead location should be

approximately 12” to 18" above the

steamroom floor.

CAUTION: NO shut-off valve should be

installed on the steam line. Do not create

traps or valleys in this line which would trap

condensation and block the flow of steam.

The steam pipe should be pitched away from

the stearnhead allowing condensation to run

back into steam generator (Preferably) Or

pitched toward the steamhead.

Rough- in a 3/4" indirect waste line to be

used for the safety valve and drain. The in-

direct drain must be in accordance with lo-

cal plumbing codes.

2)

3)

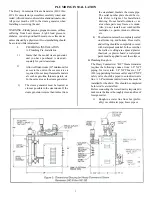

C. Steam Generator Plumbing Installation

Care must be taken when installing the steam

generator. Leave proper access for servicing

(30'’ minimum each side). (Refer to Figure 2

for typical steam generator installation.)

CAUTION: The steam generator is designed

to be used ONLY in an upright and level posi-

tion ; to do otherwise would damage the unit

and void the warranty.

If needed mount the steam generator on a

platform to allow draining into a basin or

into previously installed indirect waste line.

NOTE: Optional automatic blowdown must

be piped into the 3/4" indirect waste line.

Connect the 3/4" NPT safety valve into ihe

previously installed indirect waste line.

In areas where high water pressure may be

a problem a water hammer arrestor should

be installed. Connect the water supply to

the steam generator connection marked

“water inlet”. (See Figure 1.)

Connect the steam line from the preViously

roughed-in location to the steam solenoid

valve on the generator marked .. steam out-

let”. (See Figure 1.)

1)

2)

3)

4)

In the steamroom. place the center of the

escutcheon onto the steam pipe and Screw

the stearnhead into place. Care must be

taken not to Scratch the stearnhead or es-

cutcheon with a wrench. Be Sure the steam

slot in the stearnhead is facing down.

After the plumbing connections are complete

the electrician may finish the wiring and test

the unit.

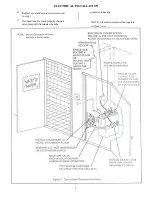

II. ELECTRICAL INSTALLATION

Electrical Pre- Installation

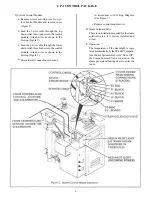

Proper electrical supply: see specification

label located above the drain valve (see Fig-

ure 1)Determine proper size of wire,voltage,

amperage. and phase for the steam genera-

tor.

Inline fuse/circuit breaker required: fu or

circuit breaker sized in accordance with

specification label. Do not install a (GFI)

Ground Fault interrupter to this equip-

ment.

B. Electrical Rough-In

Route power supply cable to the location the

steam generator will be installed before walls

are closed.

C. Steam Generator Electrical Installation

WARNING ALL POWER TO THE STEAM

GENERATOR MUST BE TURNED OFF.

Locate appropriate knockout found on top

of the steam generator. Mount proper stain

relief into knockout hole.

Strip back the power cable’ s outer insulat-

ing jacket twelve inches and insert into steam

generator. Strip back insulation 1/2" from

the incoming wires; single phase (two power

and one ground). 3 phase (three power and

one ground).

Insert ground wire into grounding lug located

on the lower left side wall of the gray elec-

trical power box.

CAUTION: Insure ground wire does not

come in contact with live electrical connec-

tions.

Locate the fuse block. found in the upper

part of the gray power box. Insert power

wires into the proper power lug terminals

on top of the fuse block and secure.

5)

A.

1)

2)

1)

2)

3)

4)

5 )

2

Locate and remove six (6) screws securing

the access cover to the gray electrical power

box. (See Figure 1.)

1)

Summary of Contents for HC-10

Page 1: ...HEAVY COMMERCIAL STEAMBATH GENERATOR OWNERS MANUAL Models HC 9 Thru HC 18 3 98 Pub No 400 G ...

Page 12: ......

Page 13: ......

Page 14: ......