months as it is an easily worn part. If it is not replaced in time before it

wears out, it will damage the motor.

•

Do not keep the motor running idly for long periods of time. Any idle run-

ning of the motor should be avoided.

•

Removal of mud, sand and other debris should be done frequently.

•

Periodically use low pressure air to remove dust from the carbon brush

and the commutator. Periodically check the connection of the carbon

brush and the commutator.

Troubleshooting

27

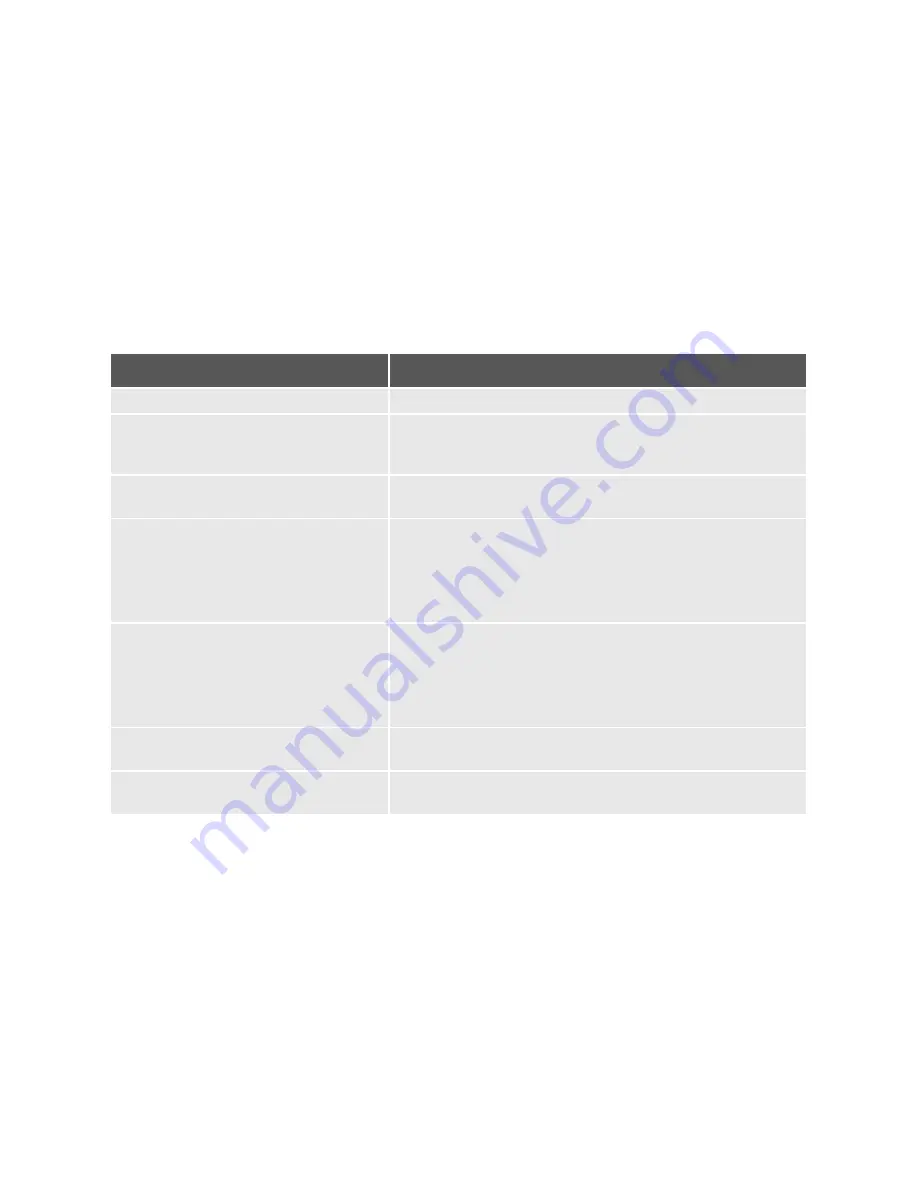

Symptoms

Possible Causes

All copper plates turn black.

The pressure of brush is incorrect.

The commutating copper turns black in a

certain order and in groups.

Short circuit between the commutating copper and the arma-

ture coil; poor welding or disconnection between the commu-

tating copper and the armature coil.

The commutating copper turns black

randomly.

The central line of the commutator deviates or its surface is not

round and smooth.

The brush wears out, changes colors and

breaks.

The motor vibrates; the clearance between the brush and

its holder is too big; the clearance between the brush and

commutator is too big; the mica between different commutator

extrudes; the brush is made with wrong materials; the brush is

wrong in type.

Sparks.

The motor is over-loaded; the commutator is not clean, round

or smooth; mica or some commutator extrude; the brush is

not ground properly; the brush is the wrong type; the brush is

jammed; the brush holder is loose or vibrating; the polarity and

sequence of magnetic poles is wrong.

The brush and its wires get hot.

Sparks from the brush; poor contact between brush and soft

wires; small section area of soft wires.

The surface of the commutator is not

smooth.

The surface of the commutator is not smooth.

Controller Maintenance

CAUTION:

Only qualified electrician should perform maintenance on the control-

ler.

WARNING:

There are no spare parts available inside the controller. No attempt

should be made to open, repair, or otherwise modify the controller. Doing so may

damage the controller and will void the warranty.