SCF-Revolution Manual

13

VENTING: TERMINATION REQUIREMENTS

In determining optimum vent termination, carefully evaluate external conditions especially when

venting directly through a wall. Since you must deal with odors, gases, and fly ash, consider

aesthetics, prevailing winds, distances from air inlets and combustibles, location of adjacent

structures and any code requirements.

1. Exhaust must terminate above combustion air inlet elevation.

2. Do not terminate vent in any enclosed or semi-enclosed area, (i.e. Carports, garage, attic

crawl space, etc.) or any location that can build up a concentration of fumes.

3. Vent surfaces can get hot enough to cause burns if touched by children. Non-combustible

shielding or guards may be required

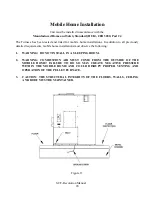

The type of installation must first be considered before determining the exact location of

the venting termination in relation ship to doors, window, cavities or air vents. See figures

4a and 4b below.

a.

Without

Outside Air connected to the unit. For These types of installations please refer

to the dimensions listed below in figure 4a.

Figure 4a

4’ (1.2 m) BELOW

a door, window, cavity, or air vent

Or

4’ (1.2 m) HORIZONTALLY FROM

a door, window, cavity, or air vent

Or

1’ (305 mm) ABOVE

a door, window, cavity, or air vent