SCF-Revolution Manual

23

APPROVED FUELS-

Pellets, Corn, Wheat, Rye, Cherry Pits & distiller’s Grain only

PELLETS & CHERRY PITS

Clinkers and Ash are by-products of pellet & Cherry pit combustion and are not caused solely by your

Furnace. Furnace performance can be quickly and severely reduced if poor quality fuel is used.

Contact your dealer for more information on APFI approved wood pellet fuels. No Standard

exists for Cherry Pits.

NOTE:

Pellets with excessive sawdust should be screened by sifting with a 1/4" mesh screen.

Store Pellets under cover on a wooden pallet or other methods to ensure they do not become rain

soaked or absorb moisture from damp or wet floors. Do not store pellets within Furnace installation

clearances or within the space required for ash removal.

CORN, WHEAT, RYE, DISTILLER’S GRAIN

These grains must have a 15% or less moisture content. The keys to satisfactory performance are: proper

operation of the stove, diligent maintenance and burning only dry, clean, quality corn, wheat, rye & Distiller’s

Grain.

NOTE: Corn, Wheat, Rye & Distiller’s Grain with excessive grain dust must be screened, by sifting with

the appropriate size mesh screening. Large pieces of cob may plug the auger.

No Standards exists for

these fuels. Inspect fuel before buying.

NOTE: Corn with excessive grain dust must be screened, by sifting with 3/16" mesh screening.

Large pieces of cob may plug the auger.

Store corn in a tight container or use other methods to ensure they do not become rain soaked or

absorb moisture from damp or wet floors. This will also prevent rodents from becoming a problem. Do

not store corn within Furnace installation clearances or within the space required for clinker removal.

The Furnace is not warranted against damage caused by poor quality corn, incorrect operation, poor

maintenance or incorrect installation.

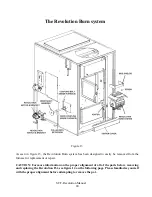

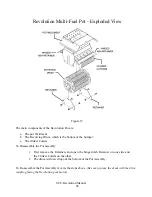

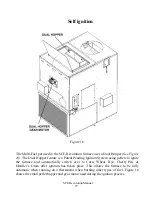

The Revolution Burn system

was specifically developed to burn most grades of pellets and many

other biomass fuels, such as Corn, Wheat & Rye (Other fuels are being tested). When burning Corn,

Wheat & Rye the Revolution pot is designed to cut the clinkers that form in the rotating drum. More

and more pellets are also being produced with higher ash content than is allowed in a Premium Pellet.

This requires a design that is capable of handling the ash produced in lower grade fuels. The

Revolution Burnpot consists of a rotating drum that is divided into 4 sections. The drum is rotated on

timed intervals to empty ash and keep the pot burning at optimum efficiency. This eliminates the need

to frequently shut the unit down for maintenance. Read the section covering Daily, Periodic and

Yearly Maintenance for proper Maintenance Schedules.

The Furnace is not warranted against damage caused by using poor pellets or other fuels not

approved for use in this furnace, incorrect operation, improper maintenance, or incorrect

installation.