User Manual

CANopen/PROFIBUS DP Gateway

GT200-DP-CO

WWW.SSTCOMM.COM

60

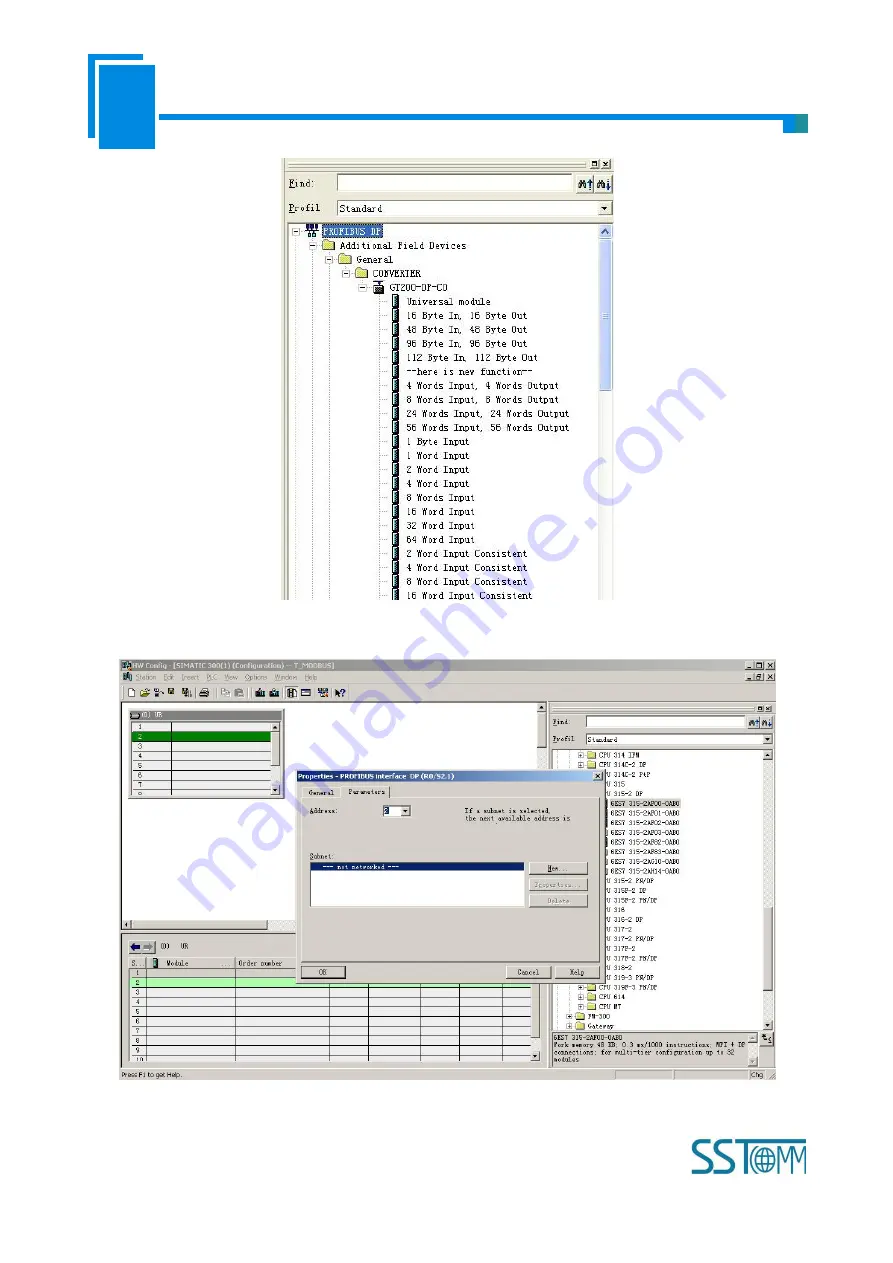

Figure 6

7. Set PLC rack, click the "Hardware Catalog \ SIMATIC 300 \ RACK-300 \ Rail"; Figure 7:

Figure 7

8. Set CPU module and select the corresponding device type and the occupied slots.