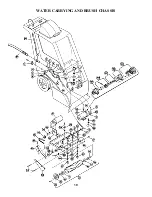

TANK & BLOWER

ITEM PART NO.

DESCRIPTION

QTY.

ITEM PART NO.

DESCRIPTION

QTY.

1

208662

Recovery Tank 110

1

41

W317D

Screw #4-40 x 1-1/4” PHP MS SS

2

208661

Recovery Tank 80

1

42

3703

Switch - Momentary

2

2

W191D1

Screw #10-24 x 3/4 RHP SS

2

43

W307D

Washer #4 Ext Tooth

2

3

217201

Dome Clasp

1

44

W385D

Nut: #4-40 Hex w/Nyloc

2

4

W106D

Nut #10-24 Hex SS

3

45

3675

Switch Plate

1

5

215005

Dome Assembly w/Gasket

1

46

980015

Washer #10 Ext Tooth

1

6

212704

Dome Assembly w/o Gasket

1

47

3716

Sleeve: Wiring

6”

7

213405

Dome Gasket

1

48

3799

Actuator Bar

1

8

3685

Intake Filter (3732 Scr.; 3733 PVC)

1

49

3686

Switch Enclosure

1

9

A12999

Lift Stop

1

50

3710

Grommet

2

10

A12998

Lift Handle

1

51

C12995

Chassis

1

11

D161C

Decal: Add Defoamer

1

53

W169D

Screw 1/4-20 x 1/2” HH CS SS

15

12

3698

Cuff Hose

2

54

W104D

Washer 1/4” Flat SS

9

13

3694

Hose 1 1/2 “ x 33” (part of 3691)

1

55

980005

Washer 1/2” Wave

2

14

3735

Cuff Hose

1

56

229750

Wheel

2

15

3695

Hose 1 1/2” x 62”

1

57

509820

Washer: Fibre

2

16

S611A

Hose Clamp

1

58

960031

Shoulder Bolt

2

17

S216P

Hose Clamp

2

59

A129671

Hinge

1

18

A13007

Adaptor 90° 110

1

60

W363D

Pop Rivet

7

A13005

Adaptor Straight 80

1

61

C12996

Bracket: Blower Mounting

1

19

A13122

Drain Hose 1 1/4” x 1.25’

1

62

W362D

Bolt 1/4-20 x 4 1/2” HH

3

20

A13006

Adaptor: Reducing

1

63

603473

Gasket Blower (effective 11/00)

1

21

S102P

Thru the Hull Fitting w/Gasket & Nut

1

64

A13504

Blower 3-Stage 115V - 110

1

22

930008

Pop Rivet

5

215201

Blower 2-Stage 115V - 80 (eff.01/01)

1

23

S400P6

0 Ring

1

S818N

Grounding Terminal for 215201

24

S400PB

Drain Valve

1

S589P

Blower 2-Stage 230V - 80

1

S400P2

Drain Valve Seal Kit

1

3738

Blower 3-Stage 230V - 110

1

S400P3

T-Handle

1

65

210901

Carbon Brush for A13504 Motor

2

25

S400PB4

Drain Elbow 2”

1

210906

Carbon Brush for 215201 Motor

2

26

W189D

Screw 1/4-20 x 3/4 HH CS SS

10

210904

Carbon Brush for all 230V

2

27

980002

Lockwasher Split 1/4”

24

66

920004

Nut 1/4-20 Hex SS

7

28

W212D

Washer 5/16” Fender Zinc

2

67

W311D

Washer 1/4” Fender

6

29

208660

Main Body - Grey

1

68

213403

Gasket: Lift Bracket (S791N1)

1

208663

Main Body - Black

1

69

A13439

Bracket: Vac Head

1

30

3687

Back Plate

1

70

C13118

Shroud

1

31

3739

Snap Bushing

2

71

C13382

Head: Vacuum

1

32

D167C

Decal: Warning Disconnect

1

72

B13000

Lift Bar

2

34

908073

Power Cord 50’

1

73

B13126

Hanger Bracket

1

35

A13020

Strain Relief

1

74

920011

Nut 1/4-20 Nyloc

3

36

911089

Switch Rocker

2

75

W340D

Screw 1/4-20 x 3 3/4 HH SC

1

37

W136D1

Screw #8 x 1/2” THP SMS B/O

6

77

980004

Washer 1/4” Flat

6

38

W387D

Screw #8-32 x 3/8 RHP M/S B/O

4

78

S209P

Hose: Exhaust 6”

1

39

980026

Washer #8 Int. Tooth

5

79

920616

Nut 1/2 NPT

1

40

W143D

Nut: Hex #8-32 SS

4

Summary of Contents for ACHIEVER 110

Page 8: ...TANK BLOWER 8 ...