11

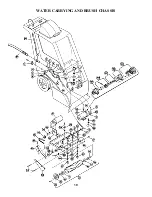

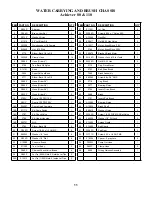

WATER CARRYING AND BRUSH CHASSIS

Achiever 80 & 110

ITEM PART NO.

DESCRIPTION

QTY.

ITEM PART NO.

DESCRIPTION

QTY.

1

S626P

Strainer

1

27

211501

Jet Cap

4

2

W166D

Brass: Jam Nut

5

28

W205D

Screw #8-32 x 1” Nylon M/S

1

3

S372P

Washer: Nylon

1

29

A13445

Rectifier

1

4

211310

90° Jet Body 3/8

2

30

920617

Nut #8-32 Hex Nylon

2

5

203308

Quick connect 1/4 Female

1

31

A13017

Motor: Brush Drive 115V

1

6

920620

Nut, .875 Stud

1

3760

Motor: Brush Drive 220V

1

7

3770

Elbow: Barb 1/8 to 3/8

2

32

200870

Bracket: Brush Motor

1

8

202050

Clamp: Hose

14

33

W124D

Washer: Lock #10 Int Tooth

2

9

S250P

Hose (Order 6”)

2

34

W329D

Nut #10-32 Hex

2

10

3766

Tee: Barb 3/8 Nylon

1

35

3719

Cog: Drive Motor

1

11

A13151

Knob

1

36

3723

Belt: Drive Brush

1

12

3824

Spool Valve w/Knob

1

37

7560

Brush Assembly

1

13

3771

Elbow: Barb 1/4 to 3/8

1

38

962062

Screw #6 x 3/4” SMS

4

14

S250P

Hose (Order 36”)

1

39

3718

Cog: Brush

1

15

S250P

Hose (Order 36”)

1

40

3677

Bearing: Rulon

1

16

S250P

Hose (Order 36”)

1

41

3722

Insert: Drive Brush

1

17

S250P

Hose (Order 6”)

3

42

3689

Brush

1

18

3785V

Pump: 100 PSI 115V

1

43

3721

Insert: End Brush

1

3821V

Pump: 100 PSI 220V

1

44

A13084

Bearing: Rulon

1

18A

204557

Pump Head Complete

1

45

A12954

Brush Shaft

1

18B

911112

Kit: Pump Switch

1

46

980612

Washer: Nylon

2

18C

3787

Kit: Check Valve

1

47

W353D

Screw 1/4-20 FHP MS SS w/Nylon

2

18D

3786

Kit: Upper Housing

1

48

980032

Washer 1/4” FH Lock

2

18E

202701

NLA

1

49

213603

Splash Guard

1

19

3765

Elbow: Barb 3/8

2

50

213602

Belt Guard

1

20

W169D

Screw 1/4-20 x 1/2 HH MS

6

51

W363D

Pop Rivet

3

21

980002

Washer 1/4” Lock

6

52

W171D

Screw 6-32 x 1/4 RHP MS

1

22

W104D

Washer 1/4” Flat

6

53

218206

Spacer - Spray Jets

4

23

C12988

Chassis: Brush

1

54

F920W

Pump Out Hose

1

24

211309

Tee: Jet Body

3

55

S453P

Clamp-Hose

2

25

S280P

Strainer/Check Valve: Brass

4

56

9600

Wiring Harness Assembly

1

26

S962P

Jet Tip (8002) Note: 2 Outside Jet Tips

2

26A

A13013

Jet Tip (11002) Note: 2 Inside Jet Tips

2

Summary of Contents for ACHIEVER 110

Page 8: ...TANK BLOWER 8 ...