6

SERVICING

ACHIEVER self-contained extractors are designed and manufactured to provide years of trouble free service with a minimum

of maintenance and service. The following recommendations are intended to assist the operator and Service Technician in

performing routine maintenance.

Failure to follow these recommendations can result in damage to your machine and diminished performance.

Warning: Always unplug your machine before performing any service. Severe personal injury could result if the elec-

trical power is not disconnected.

1. Always follow through with the recommended prestart-

up checks found in the Preparation and Transportation

section of this manual.

2. Store your machine in a dry, protected area with the

brush chassis raised and locked in place. Do not ex-

pose this machine to rain, standing water or freezing

temperatures.

3. We recommend a good, thorough cleaning after each

use. Clean the dome top, intake filter screen and recov-

ery tank with fresh, clean water. Flush the fresh water

tank and strainer periodically with clean water.

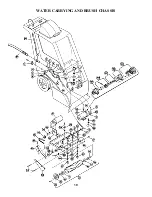

4. After continuous or repeated use, the jet tips and

strainer/check valves will need cleaning. Unplug the

cord and empty the recovery and solution tanks. Tilt the

machine backward allowing it to balance on the wheels

and drain valve. Remove the jet caps shown in the brush

chassis illustration and clean with white vinegar and a

soft bristle brush. Remove the jet tip and strainer/check

valve and soak it in vinegar until visible deposits are

dissolved, then scrub with a soft bristle brush.

Jet tips and strainer/check valves should be replaced

once a year because they tend to erode under ex-

tended use. This can cause overuse of solution and

possible streaking.

AN AUTHORIZED SERVICE CENTER SHOULD PERFORM THE FOLLOWING PROCEDURES

1. Drive Belt Adjustment and/or Replacement:

The

cogged drive belt system rarely needs tightening, so

if it becomes loose from wear, it is time to replace it.

Follow this procedure:

a) Remove the two screws that attach the hanger

bracket to the brush shroud. Then remove the

thru-bolt from the brush chassis and lift handle.

Remove the lift handle and lift stop.

b) Tilt the machine backward allowing it to balance

on the wheels and drain valve. The brush chassis

will remain on the floor exposing the brush drive

belt and motor.

c) Loosen the two motor bracket mounting bracket

mounting bolts with a 7/16

″

wrench. DO NOT

REMOVE THE BOLTS UNLESS YOU ARE

REPLACING THE MOTOR. Slide the motor

away from the brush to tighten the belt or toward

the brush for removal.

Unlike a “V” type belt, the cogged belt is run with basically

zero deflection. To test the belt tension, hold the belt between

your thumb and forefinger and twist to the side. It should

turn approximately 90

°

with little effort. If it twists more

than 90

°

, retighten the belt.

2. Pump Replacement:

a) Remove the lift stop handle as described in the

“Belt Drive” procedure (#1a).

b) Tilt the machine backward as described in the “Belt

Drive” procedure (#1b)

c) Disconnect black wire (#2) and the white wire

from the bridge rectifier (part #A130172). Also

disconnect the ground wire (this will need to be

respliced and reconnected to the ground wire on

the brush motor when reassembling). Reference

the electrical schematic.

d) Remove the two hoses from the pump. It is now

fully exposed for replacement.

e) When reassembling after any repairs, make certain

that all wire connections are properly plugged in

and secure.

f) Make all solution hose connections secure.

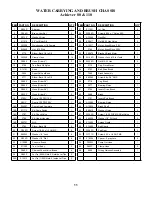

Summary of Contents for ACHIEVER 110

Page 8: ...TANK BLOWER 8 ...