4

PREPARATION AND TRANSPORTATION

PRESTART-UP CHECKS

ACHIEVER 80/110 machines are very simple and easy to

operate. Very little maintenance and service are required to

keep your machine in top operating condition.

The following procedures are recommended to maintain

the high level of performance expected from your machine.

They are also intended to identify potential safety hazards

and problems which could reduce the service life of the

machine.

READ BEFORE TRANSPORTING OR OPERATING

YOUR MACHINE:

1. Check

power cord

,

plug

and

strain relief

for worn or

damaged insulation. Repair or replace if necessary.

2. Make sure the

drain valve

is closed (T-Handle pushed

down). If the valve is left open, the vacuum is dra-

matically reduced and any recovered solution will drain

out.

3. The

knob

for the

spool valve

is located on the lower

back panel of the machine. During normal operation

as a self-contained extractor this knob is turned toward

“machine”

(horizontal position).

It should be turned

to the

“tool” position (vertical)

when a wand or other

tool is being used.1.

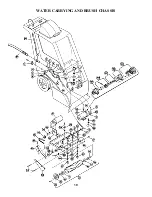

4. Lock the

brush chassis

in the up position for storage or

transport. This is done by pulling up on the

lift-handle

at the front of the machine, then resting the round lift

stop behind the bracket.

5. Inspect the

vacuum head

and

brush

by tilting the ma-

chine backwards, allowing it to balance on the wheels

and drain valve spout.

a) Vacuum Head:

Check for any damage. Burrs on

the contact surface may snag carpet fibers. Gouges,

scratches and chipped areas can reduce vacuum

performance.

b) Brush:

Inspect for damaged or missing bristles,

replace if necessary.

Return the machine to the upright position.

6. Check the

inlet strainer

for damage or debris. It is

located at the bottom of the fresh water tank. Holes in

the screen can allow contaminants to enter the pump

resulting in costly repairs. A clogged strainer will

reduce pump performance and may cause permanent

damage.

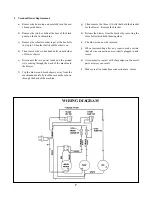

7. Remove the clear dome on top of the recovery tank.

a) Inspect for damage to the

dome

and

gasket

.

Dirt or debris on the gasket or sealing surface

of the tank can cause a vacuum leak and reduce

vacuum performance.

b) The

intake filter screen

at the vacuum hose

connection should be clean of debris and

checked periodically for any damage, replace

if necessary.

c) Ensure that the

deflector shield

and

intake

filter

are in their proper positions to prevent

recovered water from entering the vacuum

motor (blower).

Return the cover to its original position with the front

lip seated under the retaining bracket.

YOUR MACHINE IS NOW READY FOR OPERATION.

TRANSPORTING

The ACHIEVER 80/110 is equipped with large diameter

(10

″

) wheels for balance and ease of transporting. It is de-

signed to be tilted back on the wheels and pushed or pulled.

The brush chassis should be locked in the up position any

time the machine is in storage or being transported.

The large diameter of the wheels permits you to pull the

machine up stairs in the same manner you would use a

hand truck.

Never go up or down stairs with recovered

water or solution in the tanks.

Always empty the machine

completely before transporting up or down stairs or in a

vehicle.

When empty, the machine may be laid down on the side for

transporting without damaging any of its components.

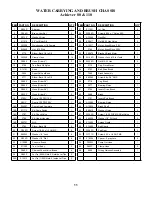

Summary of Contents for ACHIEVER 110

Page 8: ...TANK BLOWER 8 ...