21

For all VibChecker versions, measurement is started

manually from the

Measurement

display, which is

opened by pressing the

MEASURE

key from anywhere

in the menu structure.

If the instrument is on and the backlight is off, nothing

happens at first keypress, except that the backlight comes

on. Next keypress will perform the intended action.

Before measurement, make sure that ISO standard, sen-

sor settings, units etc. are set up.

To perform a vibration measurement:

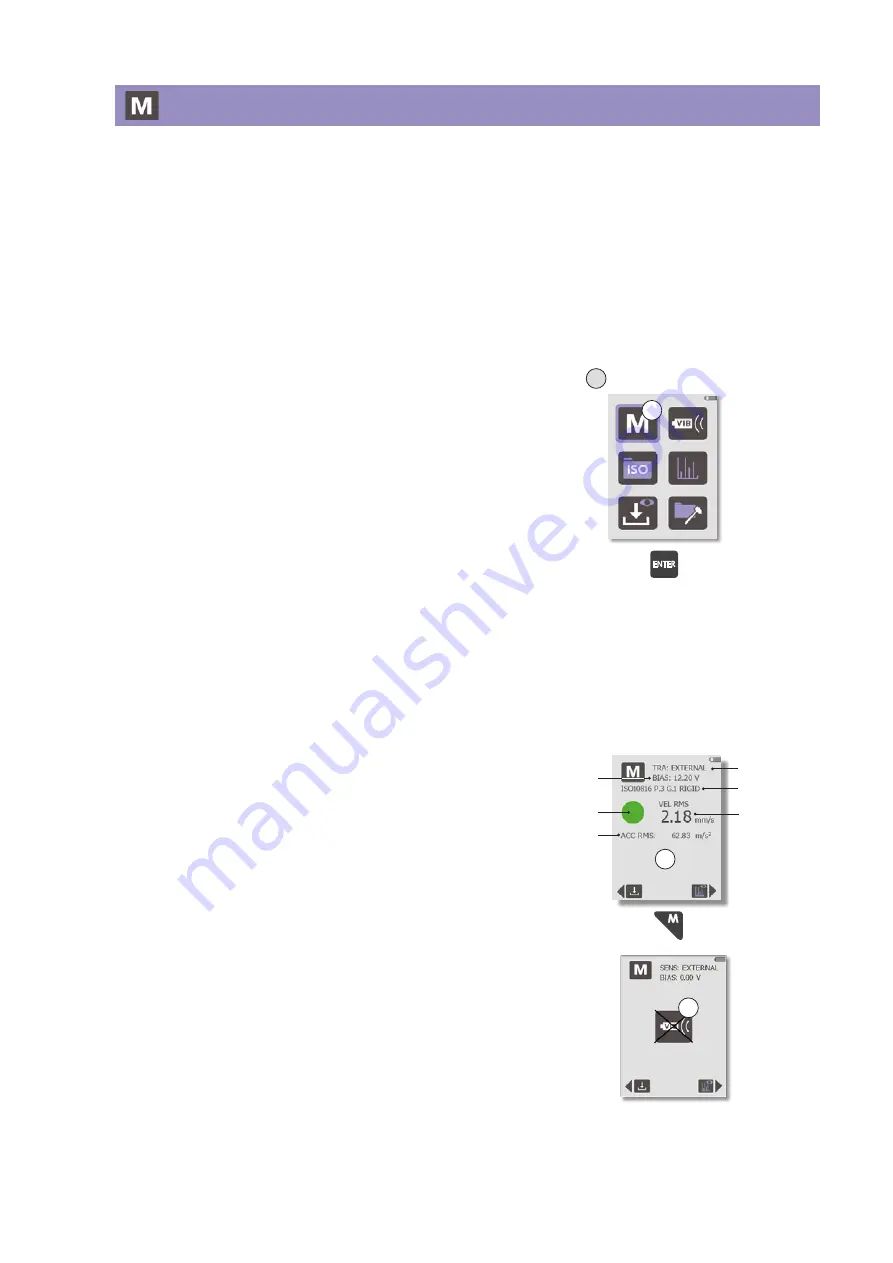

1. In the

Main

display (A), select the

Measure

icon (B)

and press

ENTER

. The

Measurement

display opens,

showing the most recent reading.

2. For a new measurement, point the VibChecker

straight at the measuring point and press the probe

tip until the rubber sleeve is in contact with the

surface (or connect the external sensor).

3. Hold the instrument steady and press the

MEASURE

key to start measurement. A single blue pixel briefly

appears at the bottom of the display, indicating that

a measurement cycle - beginning with an automatic

bias check - is in progress. The display backlight is

then turned off until the measurement is completed.

When using an external sensor, the actual measuring

starts when the defined settling time has elapsed.

As long as the

Measurement

display is still selected

and the backlight is on, no new settling time is

needed to make further measurements, unless you

switch to using the built-in measuring probe.

4. When the display lights up again, it shows the

measurement result according to the settings made

in the instrument (C). The result is shown in large

numbers, with alternative values (RMS, peak, and

peak-to-peak, depending on the selected vibration

quantity) shown in small numbers below. Depend-

ing on vibration severity (and provided that an ISO

standard was selected), the display shows a green,

yellow or red condition indicator.

When an external sensor is used, the instrument dis-

plays the bias voltage level for the current reading in

the upper part of the display. If the reading was made

with a poor sensor line, the instrument will display

Bias error (D). For further information about bias

problems, please see the “Bias voltage” section.

To return to the

Main

display, press the

BACK

key.

For information on how to store and analyze meas-

urement results, see sections ‘Storing measurement

results’ and ‘Spectrum analysis’, respectively.

Measurement

Condition

status

ISO settings

Alternative

value(s)

Measure-

ment value

Bias voltage

Sensor type

C

A Main display

B

D

Summary of Contents for VibChecker

Page 4: ...2 ...