Instruction manual for Water-cooled Air Compressor HV2/210 - 5 -

4. FAULT TRACING

The following are some of the faults that may arise in operation.

A. Compressor capacity is low and/or compressor

not supplying full pressure.

Possible cause

Remedy

Dirty, damaged or

Clean and check all valves.

worn valves

Replace defective parts.

Sticking piston rings

Dismantle rings.

Clean grooves and rings.

Replace defecive parts.

When reinstalling,

lubricate cylinder walls

with oil.

Leaking safety valves

Overhaul safety valves,

adjust to correct

lifting pressure.

Defective gasket

Replace gasket.

between crankcase

and sylinder block

Air filter blocked

Clean filter.

B. LP safety valve blows.

Possible cause

Remedy

HP valves damaged

Check and clean valves.

or dirty

Replace defective parts.

C. HP safety valve blows.

Possible cause

Remedy

Air line shut-off

Open shut-off cock.

cock closed.

Non-return valve

Remove and clean

blocked

non-return valve.

Replace defective parts.

D. Valves require maintenance too frequently.

Possible cause

Remedy

Overheating

Check cooling water

circulation and temp.

Inspect coolers and

clean if necessary.

Dirty intake air

Check suction filter.

Inferior lube oil

Change the lube oil type.

See list of

recommended types in

this handbook.

Manufactorer can

supply further

information.

Incorrect tightening of

Tighten valve

compressor valves

to specified torque.

clamping screws

to specified torque.

E. Overheating or knocking in crankcase.

Possible cause

Remedy

Defective bearings

Inspect bearings, check

clearances.

Insufficent lube oil or

Drain sump, clean and add

lube oil contaminated

new oil.

with water

Binding crankshaft

Check bearing clearances.

bearing

Replace defective parts.

F. Overheating and scoring of piston

.

Possible cause

Remedy

Piston or gudgeon pin

Replace defective

bearing incorrectly

parts, check piston

fitted

clearances, piston ring

clearances and

gudgeon pin bearing.

Deficient cooling

Check cooling

water circulation

and temperatures.

G. Excessive lube oil consumption

.

Possible causes

Remedy

Piston rings worn out

Replace piston rings.

Defective crankcase

Replace breather valve.

breather valve

Summary of Contents for HV2/210

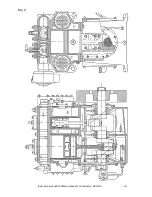

Page 16: ...Fig 1 Instruction manual for Water cooled Air Compressor HV2 210 15...

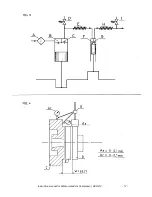

Page 17: ...Instruction manual for Water cooled Air Compressor HV2 210 16...

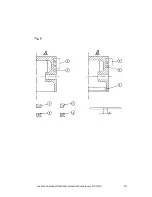

Page 18: ...Instruction manual for Water cooled Air Compressor HV2 210 17...

Page 19: ...Instruction manual for Water cooled Air Compressor HV2 210 18...