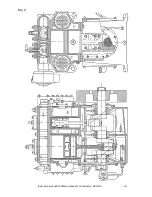

Instruction manual for Water-cooled Air Compressor HV2/210 - 10 -

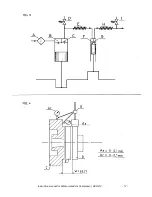

5.7. Coolers

To ensure reliable operation of the compressor it is important to keep the LP and HP coolers free from deposis of

carbon and cooling water salts etc. Insufficient cooling causes excessive air temperature and progressively

increases the formation of carbon deposits.

The cooling tubes are roller expanded into tube plates at both ends.

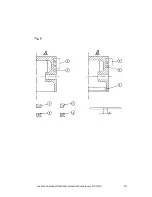

The seals at the cooler ends are O-rings, type OF special quality. Use only manufacturer's spares. To remove

the tube bundle, first loosen the cooler covers at both ends. The whole bundle can then be withdrawn by means

of two guide rods, pushed through the tubes.

Assemble in opposite sequence.

Instal new seals.

If the cooling tubes show signs of severe corrosions or wear, the complete cooler should be replaced.

5.8. Filter

The air filter

should be cleaned by means of a good degreasing agent. Blow the filter clean with compressed air

and give it a thin coating of compressor oil.

The oil filter

should be replaced complete. Replacement every 1000 hours running time is recommended.

Summary of Contents for HV2/210

Page 16: ...Fig 1 Instruction manual for Water cooled Air Compressor HV2 210 15...

Page 17: ...Instruction manual for Water cooled Air Compressor HV2 210 16...

Page 18: ...Instruction manual for Water cooled Air Compressor HV2 210 17...

Page 19: ...Instruction manual for Water cooled Air Compressor HV2 210 18...