24

Poor Product Water Quality

With any product water quality issue, you must ensure accurate calibration if you are

using a salinity meter. For general quality evaluation, your taste is always good

enough.

Membranes are not an exact science and two identical systems can have different

product quality. World health standards deem water of up to 1000 PPM of total dis-

solved solids acceptable for drinking consumption. We consider any thing below 750

PPM acceptable but not ideal, and anything below 500 PPM excellent. Factors that

could affect water quality are addressed below.

LOW SYSTEM FLOW OR PRESSURE will equate to lower product quality (higher

PPM). Aquifer systems, which have a higher feed to output pressure ratio (See

nominal pressures under Flow Test), as well as a higher feed flow/membrane

area ratio, will produce water in the 150

-

200 PPM range.

DAMAGE TO THE MEMBRANE by chlorine contamination. Flushing the system

with chlorinated water will irreparably damage the membrane. Charcoal filters

are used to absorb any chlorine which might be present in flush water. They

must be of proper specification to be suitable. There is no test for chlorine dam-

age except the process of elimination of other causes.

DIRTY OR SCALED membranes. A dirty (foreign material), scaled (mineral depos-

its), or contaminated (bacterial growth) membrane can result in poor water qual-

ity and abnormal operating pressures. If operating pressures are above normal,

then cleaning is indicated. If the system pressures are within operating normal

range, cleaning may have little result. Avoid cleaning as a diagnostic tool. Low

water quality after storage with propylene glycol can usually be remedied by ex-

tended flushing or an SC

-

2 cleaning.

MECHANICAL LEAKAGE within the membrane pressure vessel. This is an unlikely

but possible cause of poor water quality with old style Codeline pressure ves-

sels (white). The Spectra pressure vessel has a double O

-

ring arrangement that

includes a telltale hole between them so that any salt water leaking past an O

-

ring will drip into the case and not go into the product water.

If system flow (product plus brine) is 1.5 GPM or above, the membrane is clean, the

product flows are consistent with the system flow and the water quality is still not ac-

ceptable, then replacement of the membrane is indicated.

Summary of Contents for AQUIFER 360 EXPEDITION

Page 2: ...2...

Page 27: ...27 Wiring Diagram...

Page 28: ...28 John Guest Super Speedfit Fittings...

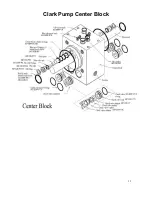

Page 35: ...35 Clark Pump Center Block...