Spearhead

Multicut

460

18

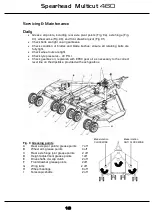

Servicing & Maintenance

Regularly

Check there is no wrapping of string, plastic, grass or other debris between

rotor boss and gearbox oil seal.

Inspect gearbox seals for leaks.

Clear grass and other debris from the deck.

Regularly check the rotor boss retaining castle nut for tightness. First remove

the split pin, select the correct size socket in 3/4” drive and fully tighten the

nut. When replacing the split pin, do not slacken the nut to align the hole,

always tighten. Failure to regularly check this nut will result in serious wear to

hub, which is expensive to repair.

It is most important that all gearbox bolts are regularly checked to be

very tight. When the machine is new there will be a ‘bedding in’ period

where very frequent checking is important.

Blades

Caution! When carrying out maintenance work on or near the blades be careful

of free-swinging blades over-centering and falling. It is recommended that

protective clothing including hardhat and goggles are worn.

The blades can be re-sharpened by grinding the cutting edges, care must be taken

that the blades are of the same weight and length after grinding. Do not overheat

when grinding as this will affect the hardness of the blades. All the blades are free

swinging and swivel on hardened steel bushes, which are replaceable. When

replacing blades, it is important that blades are replaced in sets, in order to retain

balance of the rotor. Bushes must be replaced when new blades are to be fitted.

If the blades are showing any signs of severe wear, damage or cracking, they must

be replaced immediately. Never attempt to weld the blades, as this will make them

very brittle thus extremely dangerous. Do not take risks with the cutting blades - if in

doubt, replace.

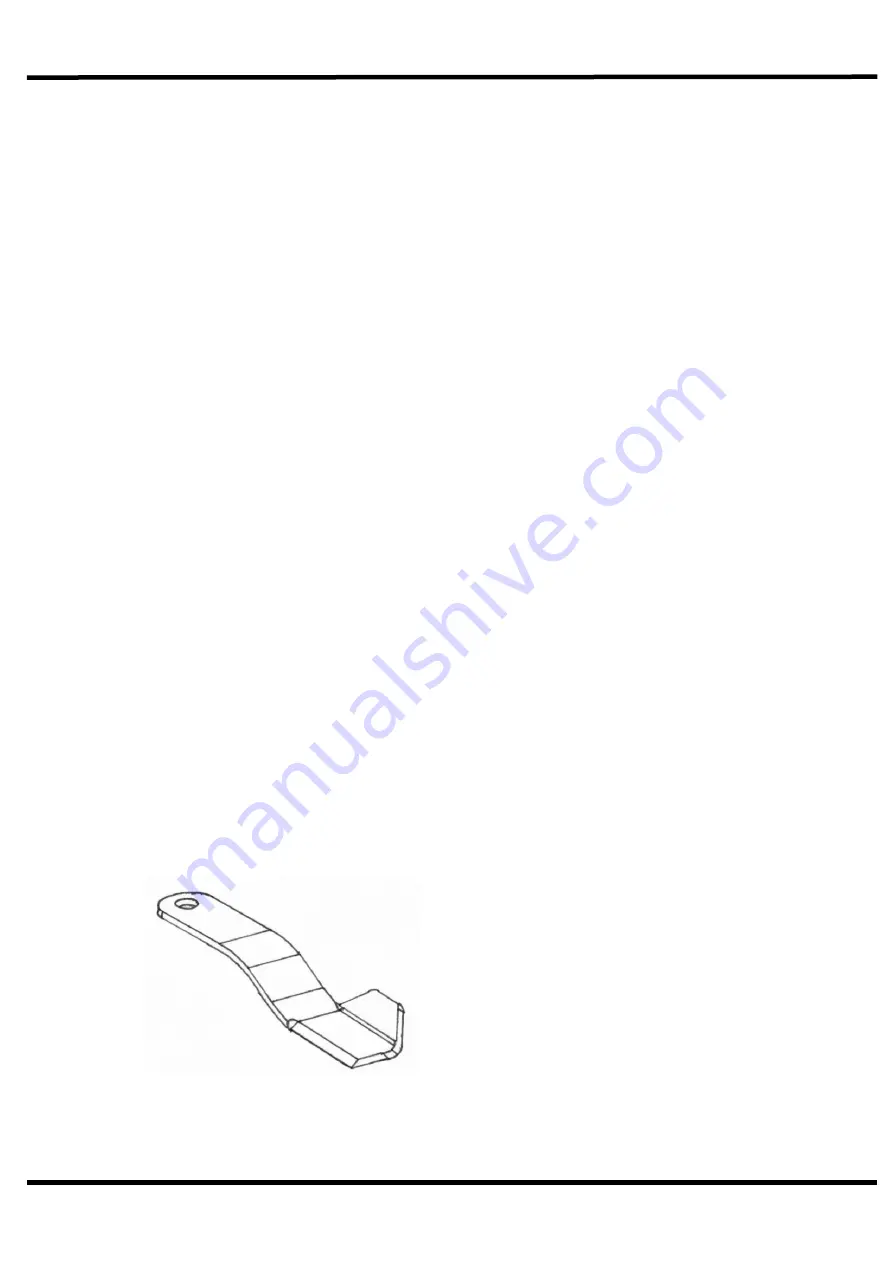

LH Blade (25”)

Part No. 7770701

Cutting Rotation

Clockwise