Spearhead

Multicut

460

17

Service & Maintenance

–

Every 8 hours

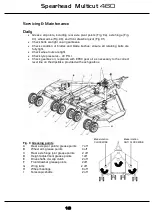

Dismantle and clean the main input P.T.O shafts sliding surfaces and

regrease; failure to do this will result in serious damage to the splitter

gearbox.

Grease all universal joints, (Fig. 10) paying particular attention to the constant

velocity joint. If under-greased this constant velocity joint will soon fail.

Grease the wing drive shaft tubes, (note the hole in the plastic tubing for

access).

Lubricate the retaining collar on all the drive shaft guards (Fig. 10).

Grease PTO inner tube and push pins (Fig. 10).

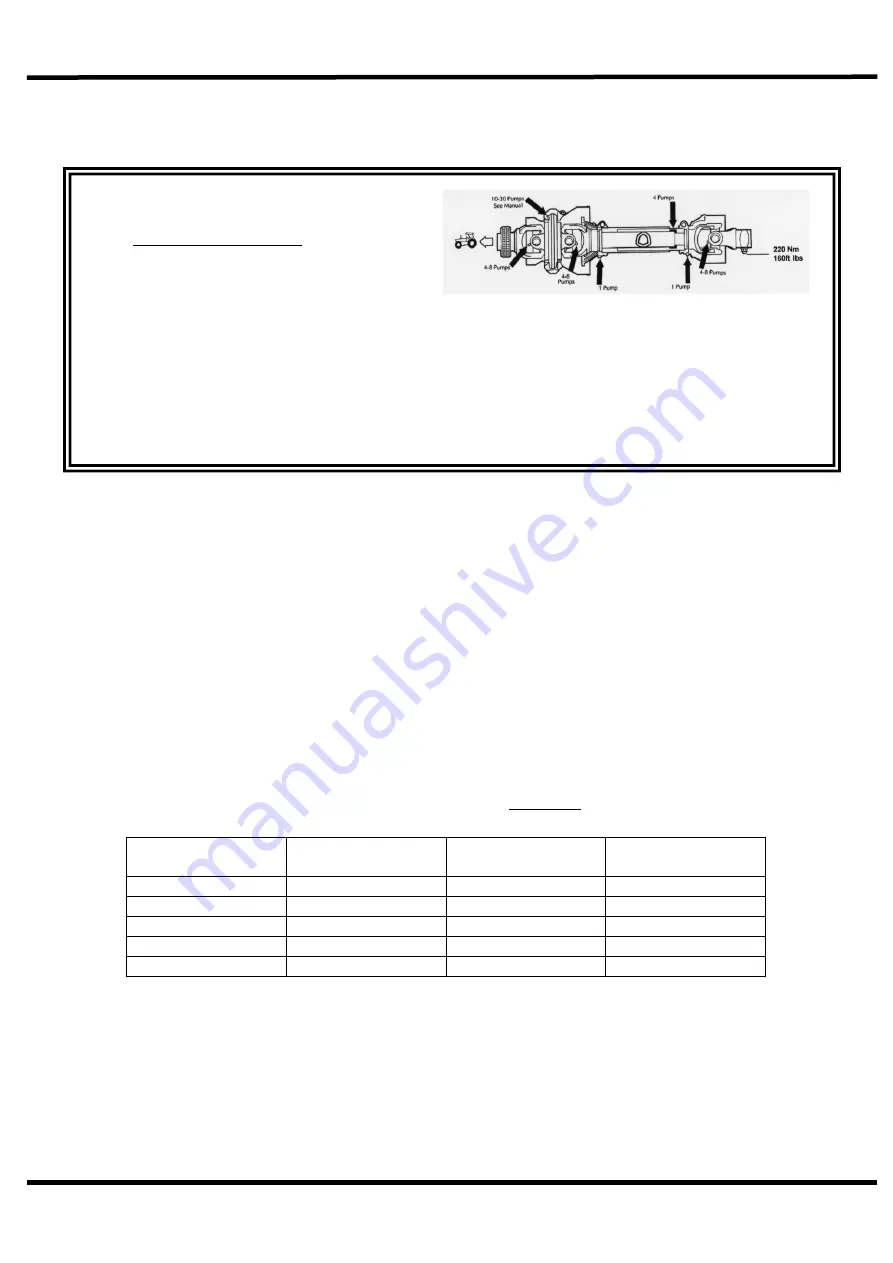

Check all bolts are tightened to the correct Torque (Fig.11).

Torque Settings

The Torque figures given below are recommended maximum settings only.

Size:

Tensile strength:

Description:

Torque setting:

Nm.

M16

8.8

Gearbox bolts

280

M16

8.8

Axle clamps

280

M24

8.8

Blade bolts

540-800

M24

12.9

Axle bolts

1500

Wheel nuts

270

For maximum life and performance, the CV body must be greased regularly. Lubricate with

the driveline in a straight position - up to 30 pumps of grease may be required.

The metal drive tubes must be greased to operate properly.

Shielding is subject to damage from abuse and weathering. Replace all damaged

components and all shielding removed during maintenance.

Do not use PTO adapters with CV drivelines. Replace special taper pin bolts only with

genuine OEM parts, periodically check tightness of nuts.

Fig. 10

Primary input shaft.