22

AFTER SALES SUPPORT

0345 605 2070

MAINTENANCE

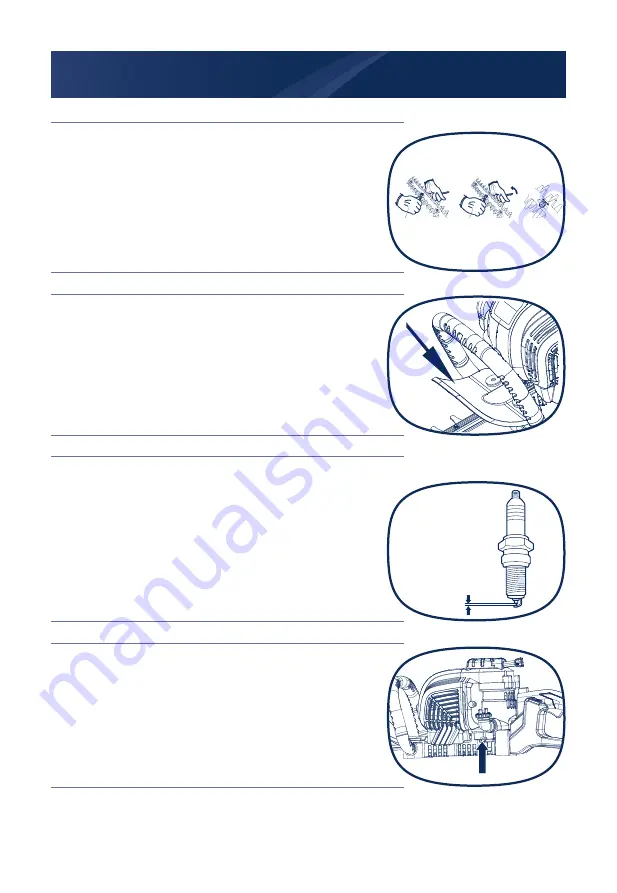

5.Check hand guard

The hand guard prevents hands from coming into

contact with the moving blades, for example, if the

operator loses grip on the front handle.Check that the

hand guard is fitted correctly and undamaged.

To ensure good cutting results it is important that the

contact pressure between the blades is correct. The

contact pressure is adjusted by turning the screws on

the underside of the bar clockwise as far as they will

go. Lock the screws using the locking nut on the top

of the bar. Check that the screws are loose enough

to allow the washers under the screw heads to slide

sideways.

0.6 - 0.8 mm

6.Inspect the Spark Plug

7.Gear maintenance

Pull out the spark plug cap and clean the dust in the

spark plug area.

Screw out the spark plug with the provided socket

wrench.Check the ceramic isolation.

Clean the electrodes (metal tip) to refresh the

surfaces.

There is a grease nipple and a plug for filling lubricant

on the gear housing. Use a grease gun to fill with

grease. This should be done after every 25 working

hours.

Summary of Contents for S2655HP

Page 29: ......