Revised Date: 2018/04/24

12

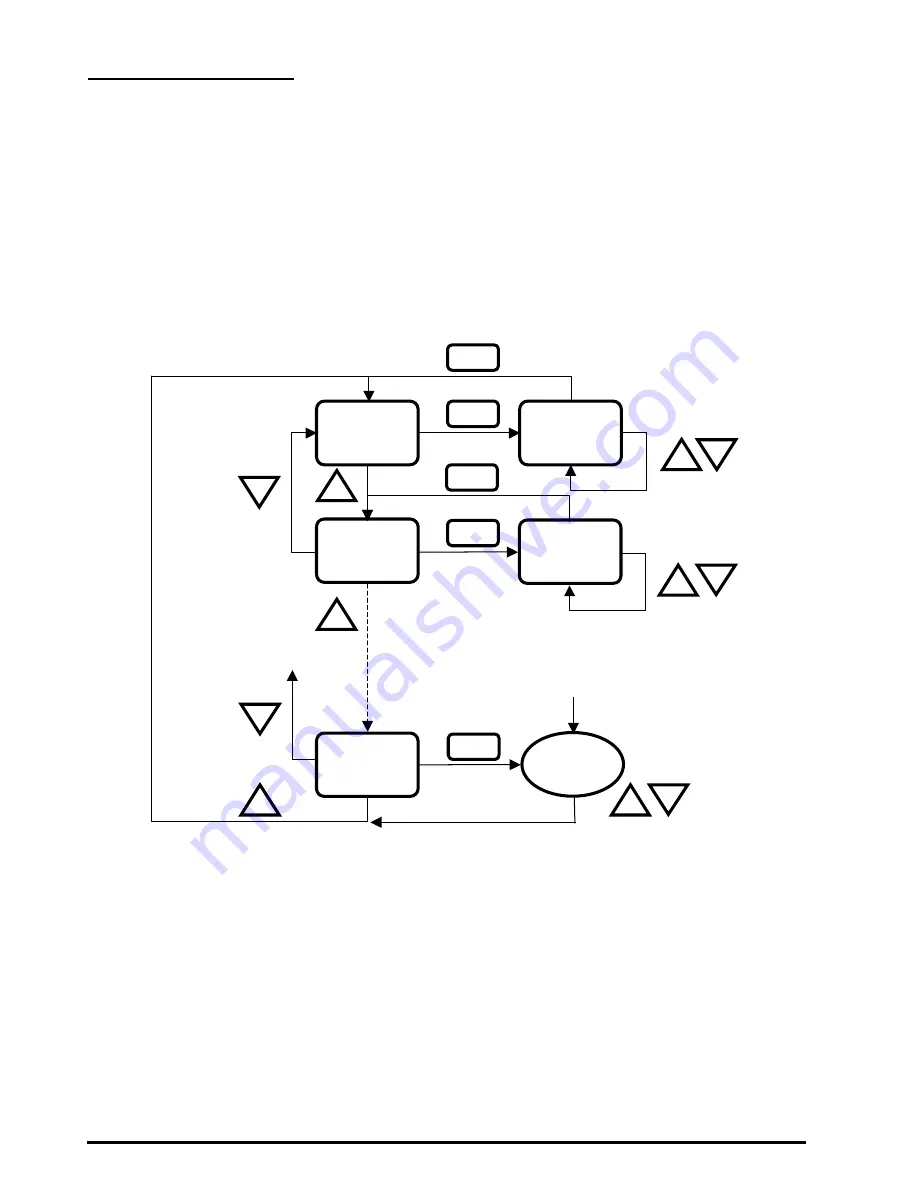

Engineer Mode Operation

This mode is highly suggested to be operated by trained engineers because it is related to system parameters that

will affect the control results. To operate:

1. Press “Up” and “Down” buttons for over 5 seconds to enter into engineer mode;

2. Press UP or DOWN button to rotate the menu item and press MODE button to enter into the item;

3. Press UP or DOWN button to change the setting and press MODE button to confirm the setting and return to

menu item selection. For no button pressed for 10 seconds, it will go back to menu item selection. The setting won’t

be changed then.

4. To leave Engineer Mode, rotate till “End” and press MODE button or leave the button intact for 10 seconds.

Engineer mode operation flow chart:

Fig. 3 Engineer Mode operation sequence

E01

E02

+

End

MODE

E01 Setting

_

+

MODE

_

User Mode

+

_

+

MODE

E02 Setting

MODE

MODE

_

Previous

No button pressed for

10s under menu item

selection

+

_

+

Press Up/down

for over 5s