For Machines Mfg. Since 7/09

Model SB1016/SB1036

-85-

S E R V I C E

Leadscrew Shear Pin

Replacement

3.

Rotate the shroud washer so the cutout in

the washer aligns with the shear pin head,

as shown in

Figure 154

.

4.

Put on safety glasses.

5.

Slide the retaining ring away from the

shroud washer so it rests against the spring-

loaded sleeve as shown in

Figure 155

.

Figure 154. Shroud washer/pin alignment.

Shear Pin

Head

Shroud Washer

Cutout

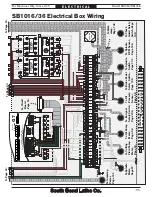

10.54mm

8.75mm

5.8mm

0.5mm

0.2mm

0.2mm

3.74mm

NOTE:

Shear Pin Material = S45C (SAE 1045)

Figure 152. Shear pin specifications.

Tools Needed:

Qty

Phillips Screwdriver #2 ........................................ 1

External Retaining Ring Pliers 90° #2 ................ 1

Magnet ................................................................... 1

Safety Glasses ....................................................... 1

To replace the shear pin:

1.

DISCONNECT LATHE FROM POWER!

2.

Clean shear pin area shown in

Figure 153

with mineral spirits, then dry with a rag.

Figure 153. Shear pin location.

Shear Pin

If the shear pin has broken, do not improvise

by inserting a roll pin, cotter pin, steel dowel,

or nail. Should the pin need to shear again,

catastrophic gearbox damage may result. Order

extras or make your own set of shear pins using

the specifications shown in

Figure 152

.

Figure 155. Shear pin access.

Retaining Ring Against

Spring Loaded Sleeve

Gap

6.

Slide the shroud washer against the

retaining ring, as shown in

Figure 155

.

There must be enough of a gap to remove the

shear pin.