-84-

For Machines Mfg. Since 7/09

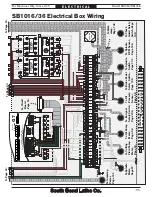

Model SB1016/SB1036

S E R V I C E

11.

Have your assistant press on the brake pedal

a few times while you watch all of the brake

linkage for any loose fasteners or worn pivot

points and pins. Tighten or replace parts as

required.

12.

Have your assistant step on and hold the

brake pedal to lock the drum in place.

13.

Remove the drum retaining cap screw shown

in

Figure 151

.

14.

Remove the brake drum, E-Clip, and shoes

shown in

Figure 151

, and the brake shoes.

15.

Use mineral spirits to clean the drum.

Then inspect it. If the drum is bell-mouthd,

cracked, or shows deep grooves, replace it.

For minor scoring, the drum can be dressed

with sandpaper or turned on a lathe.

Figure 151. Complete brake system.

Brake

Lever and

Roller

Motor Kill

Switch

Brake Pushrod

E-Clip

Brake Drum

and Shoes

Brake Lever

and Roller

16.

Clean the brake shoes with hot soapy water

and inspect. When evaluating the brake

shoes, replace the shoes as a set if the lining

thickness discussed below is

3

⁄

16

" or less, or

if the linings are loose on the rivets, or if the

bonded linings are separating from the shoe.

— If riveted linings are present, measure

the lining thickness by determining how

much lining is left before the tops of the

rivet heads will begin to score the drum.

— If bonded linings are present, view the

brake shoe from the side, and measure

the thickness of the remaining lining

before the metal brake shoe begins to

score the drum.

17.

Re-install the guards and covers, and test for

brake operation.

Drum Retaining

Cap Screw

Foot Pedal

Support Rod

Lobe Rod

and

Spindle ON/OFF

Switches