South Bend Tools

For Machines Mfd. Since 12/21

Model SB1007

-25-

P R E P A R A T I O N

5.

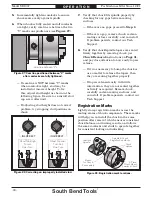

Push STOP button on control panel (see

Figure 21).

6.

Turn high/low range switch to position 1 (see

Figure 21). This will make lower spindle

speed range available.

Note:

During the next step, you may need to

use chuck key to rock spindle back and forth,

while attempting to shift, so gears will mesh.

If you do this, be sure to remove chuck key

afterward.

7.

Rotate left-hand spindle speed lever full

right, and leave right-hand lever in middle

position. As indicated on spindle speed chart

(see Figure 22), lathe will operate at a speed

of 55 RPM in this configuration.

8.

Disengage quick-change gearbox by moving

feed direction lever to neutral (middle)

position (see Figure 22).

DO NOT use jog button to help mesh gears

when changing spindle speeds or speed

range! Doing so could damage gears and

connected components.

9.

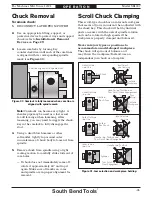

To ensure carriage components do not

move unexpectedly during following steps,

disengage half nut lever and feed selection

lever (see Figure 23).

Figure

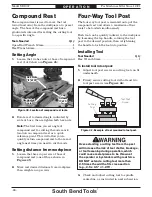

Figure 22. Spindle speed levers and feed direction

. Spindle speed levers and feed direction

lever.

lever.

10.

Turn master power switch to ON position.

The power lamp should light up.

11.

Reset STOP button by twisting it clockwise

until it pops out.

Figure

Figure 23. Carriage components disengaged.

. Carriage components disengaged.

Cross Slide

Disengaged

Feed Control

Lever

Carriage

Engaged

Half Nut

Lever

Disengaged

Feed Selection

Feed Selection

Lever

Lever

Half Nut Lever

Half Nut Lever

Spindle

Spindle

Speed

Speed

Levers

Levers

Feed

Feed

Direction

Direction

Lever

Lever