7.

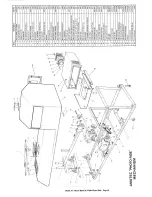

SITING OF THE PHOTO RIDE

Having determined a suitable site for the location of the Photo Ride, when siting consider the

following:-

a) The machine must be placed on level ground which is firm and free from any holes etc. The

surface that the machine stands on should not be slippery

b) Site the ride and screw down the 6 adjustable feet situated underneath the Photo Ride. These

can be adjusted using a 17mm spanner. Ensure that the 4 castor wheels have cleared the floor

and that the adjuster feet are set to make the ride secure

c) The machine should be connected to an RCB device

d) The machine should be sited clear from any other obstruction. The manufacturers

recommends the machine is sited a minimum of 6 feet from any other obstruction or

equipment

e) The power point that supplies the ride should be no further than 6 feet away and the cable

must be safely secured and protected to eliminate any risk of damage or tripping

f) The ride should not be sited in an area where it will cause an obstruction

8. ADJUSTING PICTURE QUALITY

Having sited the Photo Ride, the picture may need adjustment to quality. To ease picture

adjustments a monitor taking a PAL input and fitted with a BNC connector is useful and for

some adjustments essential. For this purpose Amutec strongly recommend the Sony Viewcam

Model

FDM030

a) With the power off, connect the monitor to the BNC connector on the rear of the printer

marked “Video Output”

b) Power up the printer and monitor. The image seen by the camera should now appear on the

monitor screen

c) Set the focus on the monitor by adjusting the focus setting on the camera lens,

remember

to lock the focus screw when correct adjustment has been achieved.

Carry out a print. If the colour achieved from the printer is unacceptable, this can be

Adjusted by the methods shown on pages 6 & 7

d) Further picture quality adjustment can be on the lens which is fitted with two types of

adjustment:

i) ALC adjustment

ii) level adjustment

Chuck ‘E’ Cheese Black & White Photo Ride Page 4