7.

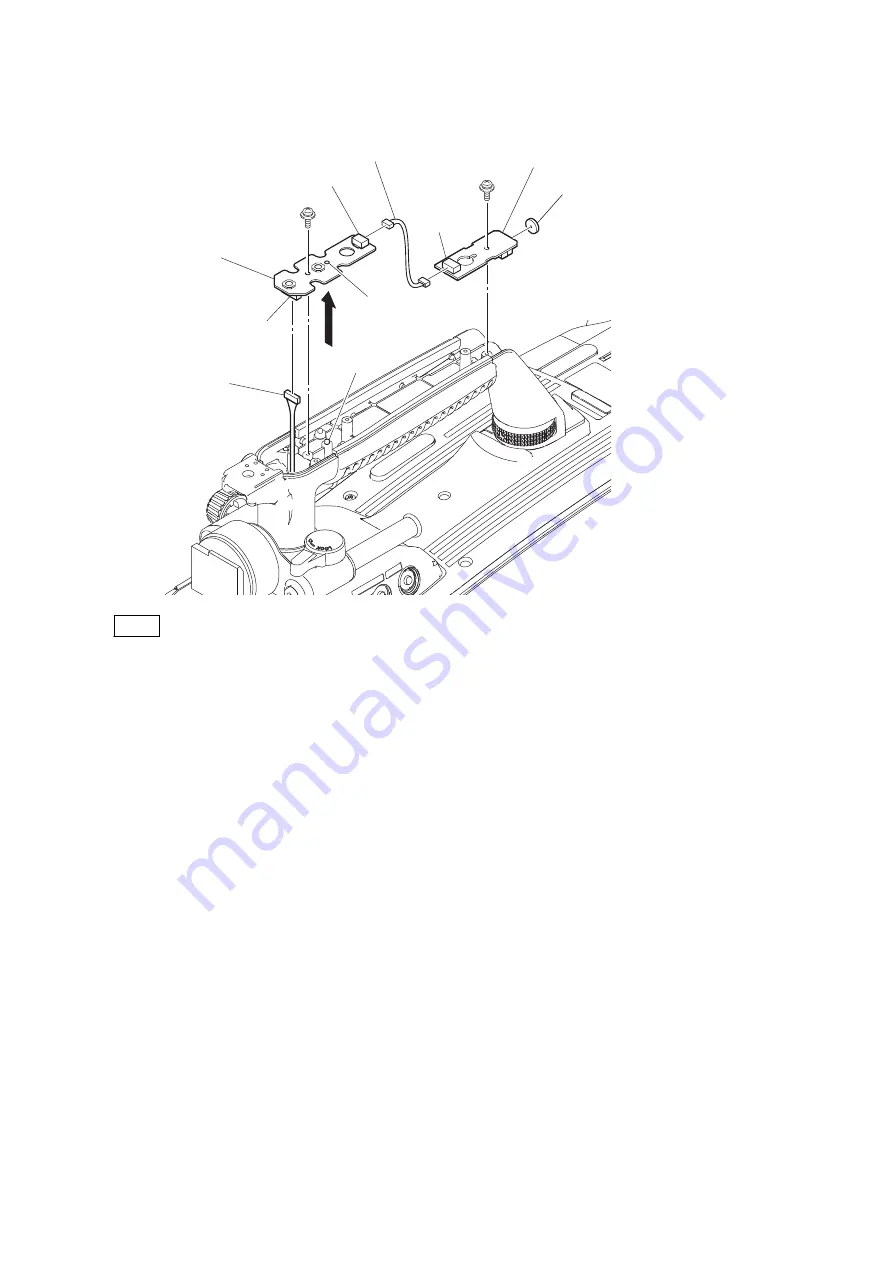

Disconnect the harness from the connector (CN1) on the SW-1524 board.

SW-1524 board

PSW2 x 5

PSW2 x 5

CN1

Hole

Boss

CN2

CN1

LE-376 board

Toggle SW cushion

Harness

Harness

Note

When installing the SW-1524 board, match the boss with the hole.

8.

Install the removed parts by reversing the steps of removal.

4-7-2.

VF Connector (CN-3422 Board)

Procedure

1.

Remove the front assembly. (Refer to

“4-5. Front Assembly” on page 4-17

)

Procedure

1.

Press the handle release button and turn the handle in the direction of arrow.

HDC4300

4-22