51

Instruction for use | Supercal 5

11.4 Arithmetic Logic Unit

Modern calculators should be able to meet a large number of user-related and technical

requirements, such as

good optical recognizability of the displays of the arithmetic unit

logical and clear menu structure

service friendliness

low costs when changing meters

Flexibility with regard to the technical adaptation of different flow sensors and

temperature sensors

Modularity over equipment with device options such as data inputs and outputs, etc.

Highest measurement accuracy and data security

In general, each calculator should be clearly assigned to a heat measuring point and

easily accessible/readable.

Electromagnetic interference and overheating at the installation site must be avoided at all

costs. All cables must be laid at a minimum distance of 300 mm from power and high-fre-

quency cables.

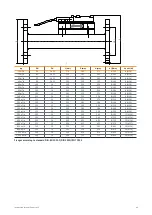

11.5 Flow Sensors

As possible/common flow sensors are possible:

Vibrating jet flow sensors

Wing and turbine wheel meters

Magnetic-inductive flow sensors

Ultrasonic flow sensors

The following application criteria can influence the selection of the flow sensor:

Type of measurement (heat/cold measuring point, viscosity of the medium, etc.)

Installation situation

Accuracy requirements for the flow sensor

Available inlet/outlet distances (measuring accuracy)

Price/performance ratio in general

In order to achieve the highest possible resolution, the pulse value (output pulses of the flow

sensor per volume passing through) should always be low.

The installation location of the flow sensor (“cold side” or “warm side”) is just as important,

because the conversion from the volume passing through to the mass passing through takes

place at the temperature assigned to the installation location.

As a rule, the flow sensor is installed where the environment temperature is closer to the

room temperature.

This results in a higher measuring accuracy and a longer service life of the flow sensor.

11.6 Flow Measurement

Type-approved flow sensors with a pulse or frequency output can be connected to the

Supercal 5 .

The calculator has the following input pulse values:

up to 999,999 pulses/litre

up to 999,999 litres/pulse

Its flow rate is determined with a suitable flow sensor.

A pair of temperature sensors determines the “Warm pipe temperature” and the

“Cold pipe temperature” of the heat transfer medium. As soon as ΔT > 0,2 K, the energy

consumed is calculated.

Accordingly, the cooling energy is cumulated when the temperature difference

< – 0,2 K is reached and the “cold pipe temperature” < 18°C (the threshold value can

be programmed or customized on demand).