Lit. No. 70451, Rev. 06

23

November 1, 2018

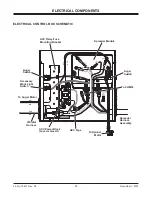

MAINTENANCE

LUBRICATION

To keep your spreader running smoothly, lubricate the

grease

fi

ttings (as shown below) after each use and at

the end of each season.

AFTER FIRST USE

Tighten all mounting fasteners.

AFTER EACH USE

• Wash unit after each use to prevent material

build-up and corrosion.

NOTE: Do not spray water directly on the auger

bearing and seals.

• Apply dielectric grease on all electrical

connections to prevent corrosion.

AT END OF EACH SEASON OR

AFTER EXTENDED STORAGE

• Apply dielectric grease on all electrical

connections to prevent corrosion at the beginning

and end of the season and each time the power

plugs are disconnected.

• Wash out the hopper and rinse off all external

surfaces to prevent material build-up and corrosion.

• Paint or oil all bare metal surfaces at the end of

the season.

• Apply a small amount of light oil to latches as needed.

CAB CONTROL

Unplug the cab control from the control harness at

the end of the season or when the hopper is removed

from the vehicle.

FUSE REPLACEMENT

If a problem should occur and fuse replacement is

necessary, the replacement fuse must be of the same

type and amperage rating as the original. Installing a

fuse with a higher rating can damage the system and

could start a

fi

re.

RECYCLE

When your spreader has performed its useful life,

many of its components can be recycled.

WARNING

Never remove the spreader with material in

the hopper.

CAUTION

Disconnect electric power at spreader

electrical wiring harness connection and

tag out, if required, before servicing or

performing maintenance.

CAUTION

DO NOT leave unused material in

hopper. Material can freeze or solidify,

causing unit to not work properly.

Empty and clean after each use.

Rear Auger

Bearing

Front Auger Bearing